Humidity sensor based on MXeneTPU composite film to assist in human respiratory monitoring

Humidity sensing is an important non-invasive strategy for respiratory monitoring,

as the exhaled airflow has a higher temperature and humidity than the inhaled airflow.

Therefore, respiratory frequency can be monitored by measuring the humidity changes

during the breathing process. Humidity sensors can be prepared by embedding sensing

materials into flexible substrates. Thermoplastic polyurethane (TPU) electrospun nanofibers

have the characteristics of large specific surface area, high porosity, and good flexibility,

making them commonly used as flexible substrate porous materials. MXene has excellent

water sensitivity and conductivity, making it very suitable as a sensing material in humidity

sensing applications.

According to Maims Consulting, a joint research team from the First Affiliated Hospital

of Xi'an Jiaotong University and the School of Advanced Materials and Nanotechnology of

Xi'an University of Electronic Science and Technology recently published a paper titled

"MXene/TPU Composite Film for Humidity Sensing and Human Response Monitoring"

in the Advanced Sensor Research journal. The first author of this paper is Tianqing Liu

from Xi'an University of Electronic Science and Technology, and the corresponding authors

are Chief Physician Zhang Guangjian from the First Affiliated Hospital of Xi'an Jiaotong

University, Professor Wu Weiwei and Lecturer Du Tao from Xi'an University of Electronic

Science and Technology.

This research work utilized the excellent hydrophilicity and conductivity of MXene to

coat MXene nanosheets onto chitosan modified TPU electrospun nanofibers through

electrostatic interactions, and prepared MXene/TPU composite films. Based on this film,

humidity sensors were prepared. Based on the principle that the distance between MXene

nanosheets is affected by changes in water molecule concentration, thereby changing tunnel

resistance, MXene/TPU humidity sensors exhibit many characteristics such as fast response

speed (12 seconds), wide humidity response range (11% -94% relative humidity (RH)), low

hysteresis (<7% RH), and high repeatability. This humidity sensor can be integrated into a

mask to distinguish different respiratory patterns of the human body and accurately monitor

respiratory frequency signals during different movement states. It has broad application

prospects in the field of respiratory monitoring.

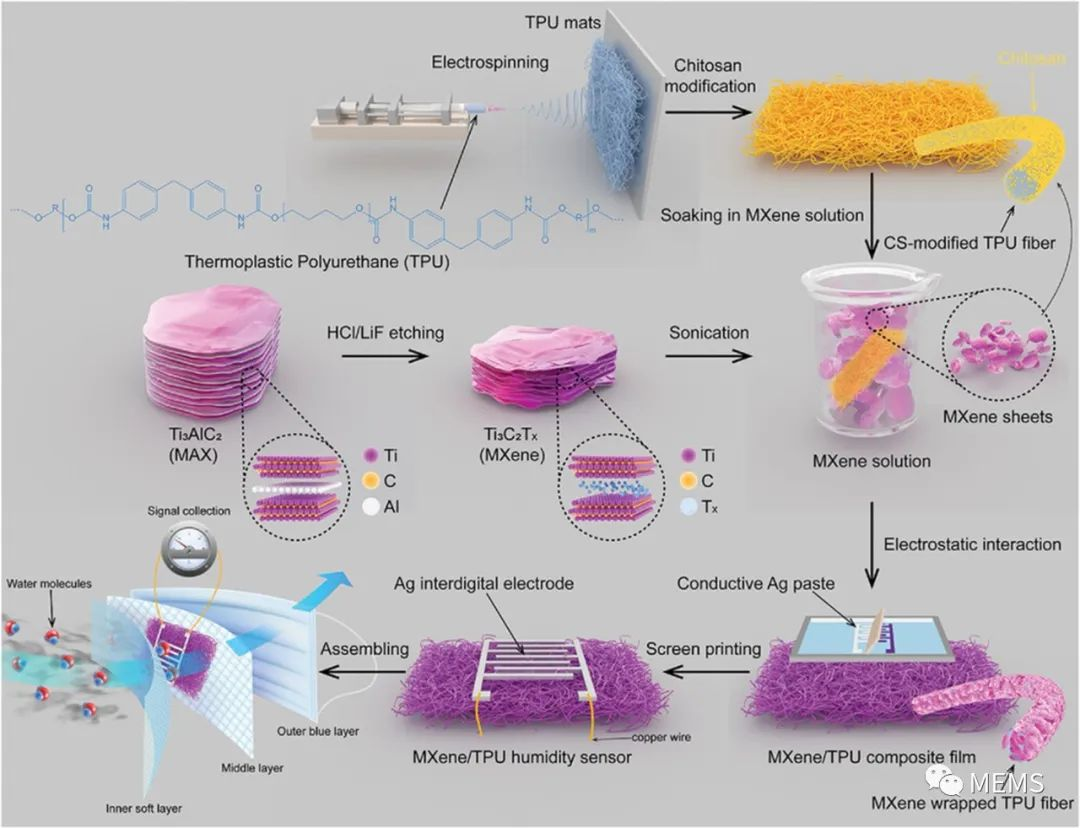

Researchers prepared MXene/TPU humidity sensors by coating MXene nanosheets on

chitosan modified TPU pads. The entire preparation process can be divided into three steps

(as shown in Figure 1): (1) Preparation of Ti3C2Tx? MXene nanosheets; (2) Preparation and

modification of electrospun TPU pads; (3) Prepare MXene/TPU humidity sensors.

Figure 1 Schematic diagram of the preparation process of MXene/TPU humidity sensor

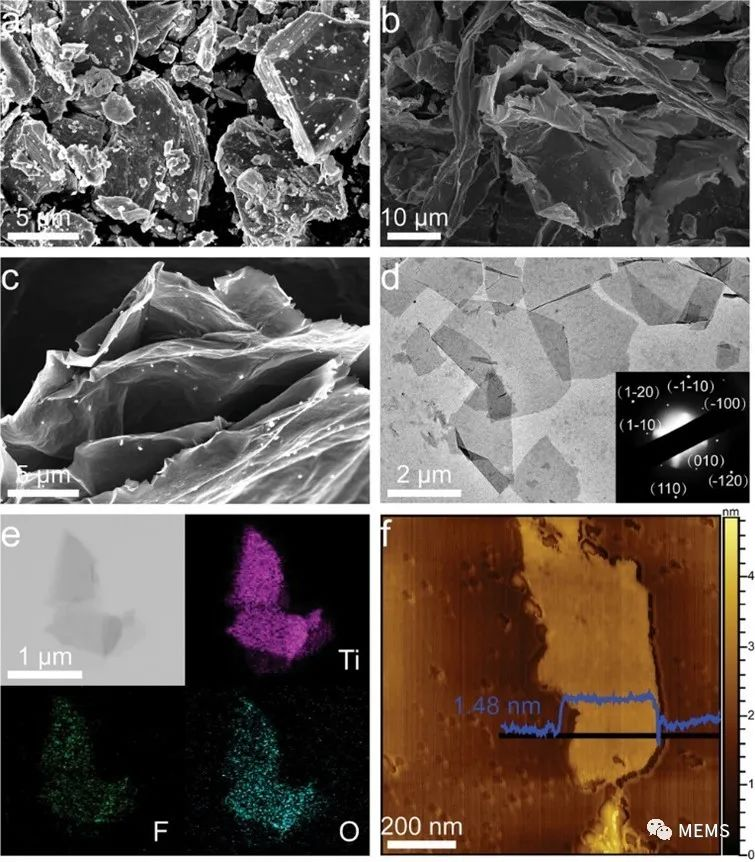

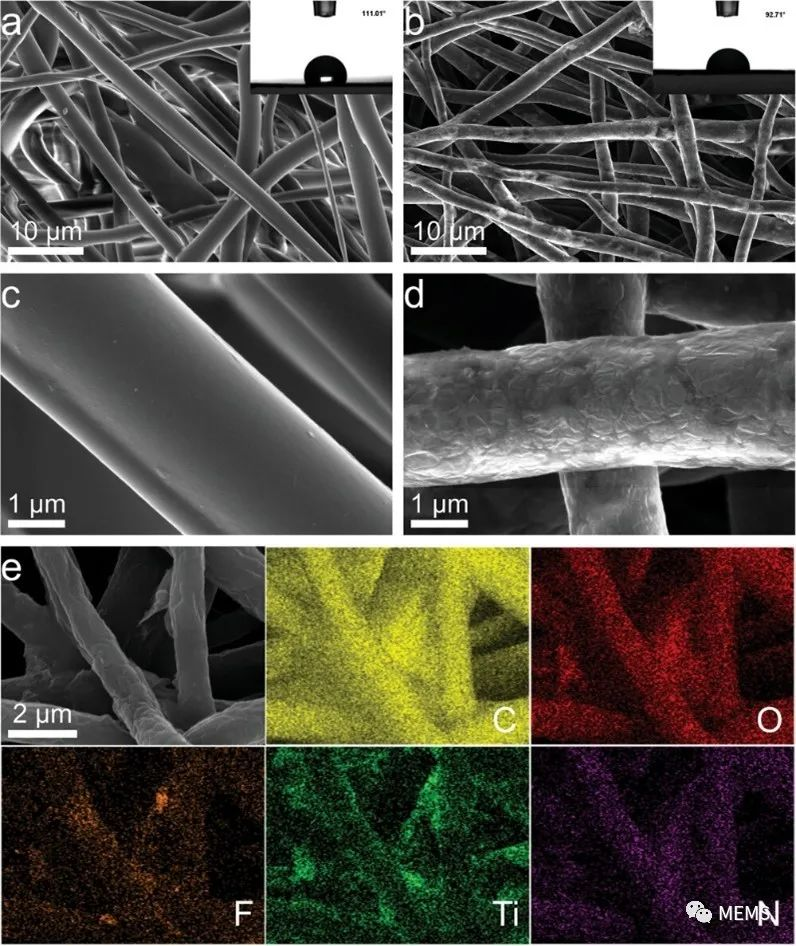

Subsequently, the researchers measured and characterized the prepared MXene sensing

material and electrospun TPU pad, as shown in Figures 2 and 3.

Figure 2 Characterization of MXene sensing material

Figure 3 Characterization of electrospun TPU liner

Subsequently, in order to study the chemical properties of MXene/TPU composite films,

researchers used techniques such as X-ray diffraction (XRD), Fourier transform infrared spectroscopy

(FT-IR), Raman spectroscopy (Raman), and X-ray photoelectron spectroscopy (XPS) to characterize

them. The results are shown in Figure 4. These results validate the successful preparation of

MXene/TPU composite films and their potential as humidity sensitive materials. Next, Ag interdigital

electrodes are integrated into MXene/TPU composite films using screen printing technology, and

connected to external circuits through copper wires.

Figure 4 Chemical characterization of MXene/TPU composite film

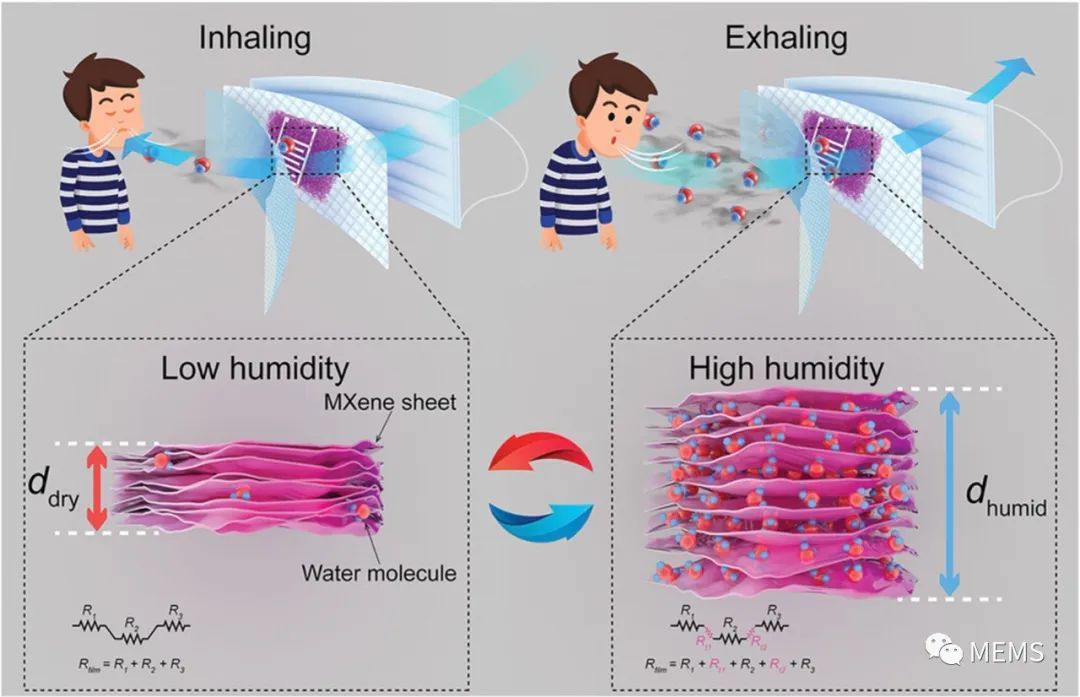

The sensing mechanism schematic diagram of the MXene/TPU humidity sensor is shown

in Figure 5. As the humidity increases, the spacing between MXene nanosheets increases,

resulting in an increase in the tunnel resistance at the connection (as shown in Figure 5, right).

When the humidity decreases, the spacing between MXene nanosheets decreases, causing the

total resistance to recover (as shown on the left in Figure 5).

Figure 5 Schematic diagram of the sensing mechanism of MXene/TPU humidity sensor

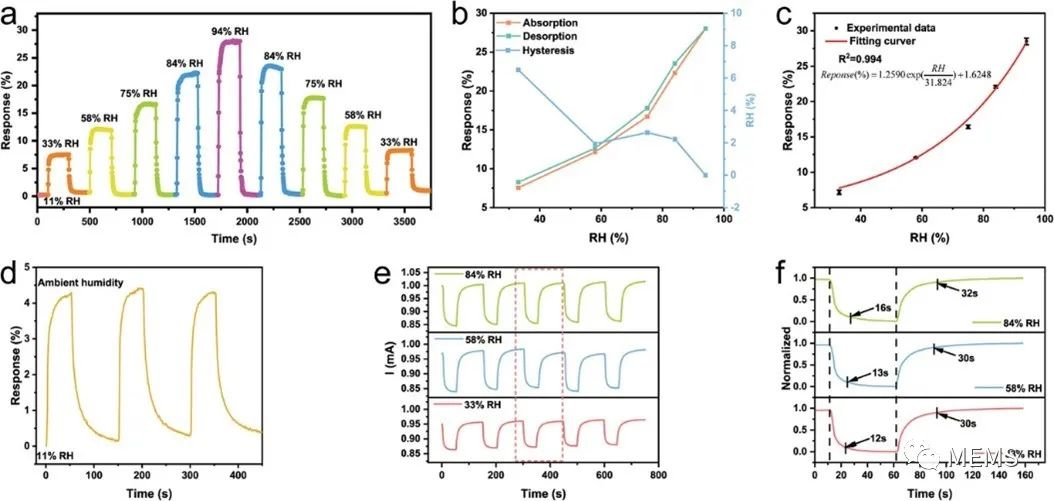

Based on the above humidity sensing principles, a self-made sensing device was used to

characterize the humidity sensing performance of the newly prepared MXene/TPU humidity

sensor, as shown in Figure 6. The performance of the MXene/TPU humidity sensor is: a humidity

response range of 11% -94% RH, hysteresis of<7% RH, high repeatability, and a response speed

of up to 12 seconds.

Figure 6 Performance characterization of MXene/TPU humidity sensor

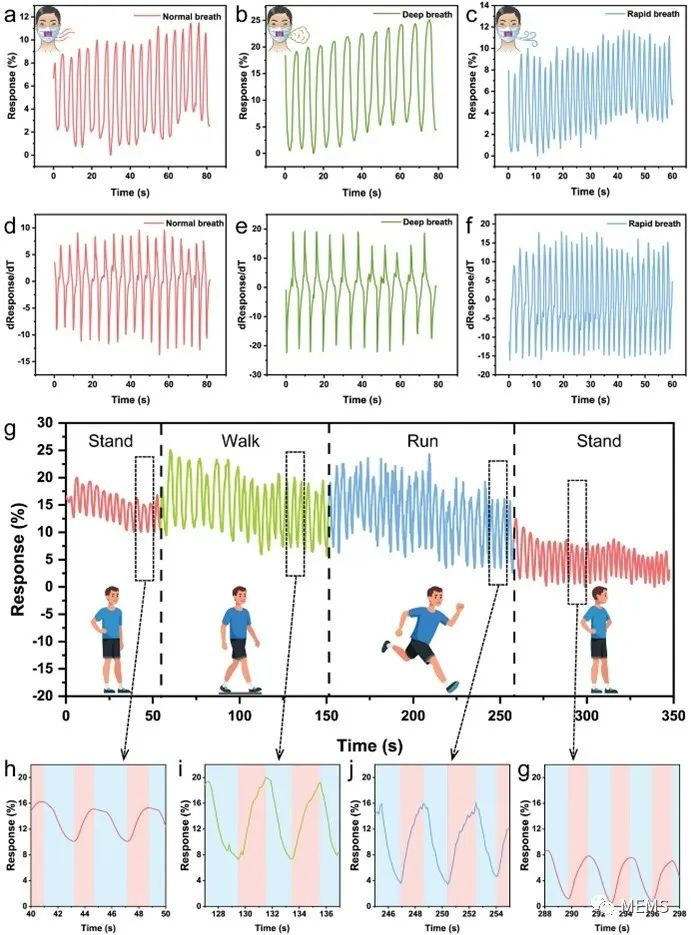

Finall to analyze physiological information from human respiration, researchers integrated

the MXene/TPU humidity sensor into the mask, and the relevant test resy, in orderults are shown

in Figure 7. Figures 7a to 7c show the monitoring results of three typical respiratory patterns in

a single subject wearing an integrated humidity sensor mask. The results from Figures 7d to 7h

indicate that the MXene/TPU humidity sensor can be used for human respiratory monitoring,

providing valuable respiratory monitoring information under both resting and different exercise

states.

Figure 7 Test results of respiratory monitoring using a mask with integrated MXene/TPU humidity sensor

In summary, researchers successfully prepared MXene/TPU humidity sensors by coating

MXene nanosheets on chitosan modified TPU electrospun nanofibers using electrostatic

interactions. The morphology and chemical properties of MXene/TPU composite films were

characterized by methods such as SEM, EDS, XRD, FT-IR, Raman, and XPS, confirming the

effective binding of MXene sensing materials to TPU substrates. The MXene/TPU humidity

sensor has good performance such as fast response speed, wide humidity response range,

low hysteresis, and high repeatability. The researchers also integrated the humidity sensor

into the mask to identify different breathing patterns and accurately monitor respiratory

signals under different movement states. This paper explains the principle of humidity sensing

by simulating the effect of changes in water molecule concentration on the spacing of MXene

nanosheets, thereby altering the tunneling resistance. This research work not only provides a

new perspective for the development of humidity sensors, but also provides new ideas for the

development of MXene/polymer sensors based on resistance changes.

This research was funded and supported by Shaanxi Provincial Key Research and Development

Program (2022ZDLSF01-04 and 2020GXLH-Y-012), the Open Fund of the State Key Laboratory of

Solid Lubrication of Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences (LSL-1905),

and the Science Foundation of Shandong Advanced Materials and Green Manufacturing Laboratory

(Yantai).