A brief introduction to the evaporation boat in vacuum coating

1、 Materials used for evaporation boats

As an evaporation source for vacuum coating, the evaporation boat must be

made of materials that are resistant to high temperatures, metal solution corrosion,

strong thermal shock resistance, conductivity and heat generation, and have a certain

mechanical strength. Based on the above requirements and relevant literature review,

it was found that carbon graphite materials and ceramic materials are mainly used as

evaporation boat materials.

Carbon graphite materials have the following characteristics: firstly, carbon materials

have good high-temperature resistance and thermal stability, exceeding the temperature

required for vacuum coating, so they are stable and reliable. Secondly, although carbon

is a non-metallic material, it has good electrical conductivity and low resistance. Thirdly,

carbon graphite materials have a low coefficient of thermal expansion and good thermal

shock resistance. When used at high temperatures, they have good dimensional stability

and are less prone to fragmentation when subjected to significant temperature changes.

Fourthly, carbon graphite materials have better chemical stability compared to other

materials. However, it is a porous material with a porosity of about 10% -30%. During the

coating process, the evaporation boat is prone to fracture, resulting in the inability of

current to pass through and affecting production.

BN has high thermal stability, chemical stability, and electrical insulation, as well as

high thermal conductivity, good dielectric properties, easy processing of products, and

high melting point. The composite of BN and TiB2 can improve the thermal conductivity

of the material, obtaining appropriate resistivity and resistance temperature coefficient.

The performance indicators of

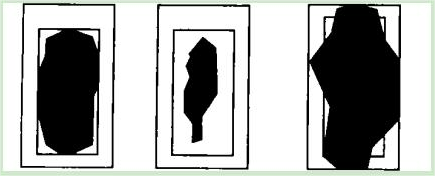

2、 Arrangement of evaporation boats

There are mainly two types: linear arrangement and staggered arrangement. When

using a linear arrangement, due to issues such as electrical contact and poor heat

conduction, the evaporation boat expands and moves in the clamp during the heating

process, which can easily cause instability in the evaporation process. Adopting a

staggered evaporation boat system, the vapor clouds of each evaporation boat present

a mutually supportive state, and even during high-speed coating, high uniformity can

still be achieved.

3、 Temperature control of evaporation boat

The main purpose of controlling the temperature of the evaporation boat is to meet

the thickness requirements of the aluminum layer, produce a uniformly thick aluminum

film at the ideal coating speed, and extend the service life of the evaporation boat. In

order to maximize the amount of aluminum evaporated, the entire tank surface of the

evaporation boat should be utilized as much as possible. There are three types of surface

conditions on the aluminum melt pool at different temperatures.

The first type is the evaporation boat with the largest aluminum melt pool, and the

aluminum does not flow to the end or beyond the side of the evaporation boat in the

evaporation tank. In this case, the uniformity of the aluminum film is good. The second

type is that the operating temperature of the evaporation boat is too high, resulting in a

decrease in the aluminum melt pool. In this case, in order to maintain the coating speed,

the aluminum evaporation rate within this small area will be increased. While the uniformity

of the coating will deteriorate, the service life of the evaporation boat will also be reduced

due to the high temperature. The third type is that the temperature of the evaporation boat

is too low, and aluminum will overflow the evaporation tank, leading to poor uniformity of

the aluminum layer and even causing aluminum splashing.

As the usage time increases, the aluminum slag accumulated in the evaporation tank

reduces the area of the molten pool. In order to maintain the original evaporation rate,

the temperature of the evaporation boat will be increased, which will reduce the service

life of the evaporation boat. Therefore, between each coating cycle, the surface aluminum

slag is brushed clean and graphite is brushed.

4、 Corrosion of evaporation boats and solutions

Metal aluminum is very stable in solid state, but molten aluminum has strong

corrosiveness. Aluminum penetrates between TiB2 particles to corrode BN on the surface,

reducing BN in the evaporation boat structure and causing groove like corrosion, which

affects the lifespan of the evaporation boat.

Firstly, liquid aluminum is spread out in the evaporation tank. At high temperatures,

liquid aluminum reacts with BN in contact to generate AlN. After the BN around TiB2

particles has reacted, TiB2 particles accumulate on both sides of the molten pool due to

the promotion of the aluminum liquid. As the evaporation time goes on, the reaction layer

continues to increase, and the thickness of the evaporation boat decreases, gradually

increasing its resistance. While keeping the voltage at both ends of the evaporation boat

constant, the increase in resistance leads to a decrease in heating power, resulting in a

decrease in the temperature of the evaporation boat.

Secondly, as the use time of the evaporation boat prolongs, TiB2 particles continuously

deposit on both sides of the molten pool, reducing the effective area of the molten pool.

In order to maintain the original total evaporation rate, the temperature of the evaporation

boat will inevitably increase. When the voltage cannot be increased to increase the temperature

of the evaporation boat anymore, it indicates that the evaporation boat has failed.

Finally, the aluminum in the evaporation process is introduced through a wire guide

tube and then melted into other parts of the evaporation tank. The corrosion reaction on

the surface of the evaporation boat is not uniform due to the flow erosion of aluminum

liquid and the mechanical impact of high-speed imported aluminum wire, which leads to

uneven changes in resistance throughout the boat body. In the parallel current direction,

due to the series connection of various resistors, under the same current, the power in

areas with high resistance is higher than that in areas with low resistance; In the direction

perpendicular to the current, the resistance at each point is in parallel. When the voltage

is the same, the power at the places with low resistance is higher than that at the places

with high resistance. This will seriously change the temperature distribution of the entire

boat body, causing uneven flow direction and evaporation of the aluminum liquid.

To reduce corrosion and improve the life of the evaporation boat, the following methods

can be used:

(1) Choosing an evaporation boat with good compactness and high density, which has

fewer gaps between particles, can reduce the chances of aluminum liquid penetrating

and corroding BN.

(2) Keep the impurities around the evaporation tank clean every cycle to ensure a stable

molten pool area.

(3) Delay increasing the temperature of the evaporation boat and minimize the temperature

of the evaporation boat as much as possible while ensuring that the coating requirements

are met.