Xijiaotong University small: discovery of a new mechanism of dislocation regulating the growth of zirconium hydride

Zirconium alloy has excellent comprehensive properties and is widely used as cladding and pressure tube of nuclear fuel. Zirconium alloy is easy to absorb hydrogen to form brittle zirconium hydride distributed along the base plane, which accelerates the embrittlement and failure of zirconium alloy cladding. Clarifying the nucleation and growth mechanism of hydride is of great significance to inhibit the precipitation of hydride and prolong the service life of zirconium alloy cladding. This paper reveals a new mechanism of precipitation and growth of zirconium hydride under dislocation control. In situ study shows that the hydride growth process presents an alternating sequence of dislocation emission hydride growth dislocation re emission hydride re growth.

According to the migration characteristics of atoms, the solid-state transformation of metals can be divided into diffusion type transformation and non diffusion type transformation (such as martensite transformation). There is another kind of transformation that not only produces shear, but also needs the assistance of solute atom diffusion, that is, mixed type transformation, such as bainite transformation. The precipitation of zirconium hydride has similar characteristics. It is generally believed that the slip of shawclay dislocation and the diffusion of solid solution hydrogen atoms coordinate the precipitation of hydride. However, the detailed mechanism of precipitation and growth is lack of in-depth and intuitive in-situ research. In addition, the hydride in zirconium alloys is always wrapped by complex dislocation structures with bird's nest or butterfly shape. Even if the hydride decomposes during heating, the dislocation structures around it can still be preserved. Therefore, clarifying how to form such a complex dislocation structure in the precipitation process of zirconium hydride and clarifying the relationship between the complex dislocation structure and the phase transition of zirconium hydride are of great significance to understand the phase transition of zirconium hydride, regulate the precipitation of hydride, and inhibit the hydrogen embrittlement of zirconium hydride.

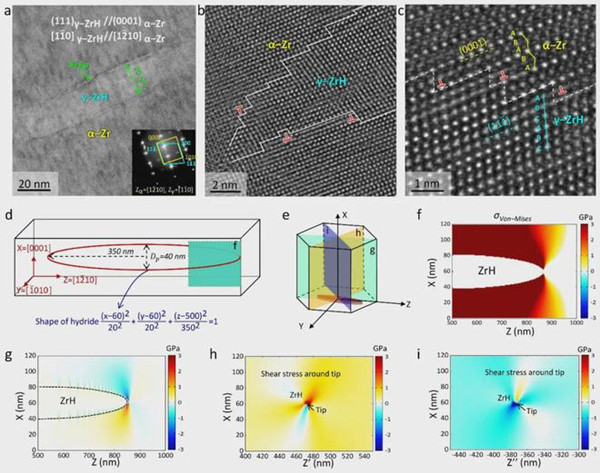

The precipitation of zirconium hydride usually occurs in the cooling process from high temperature to room temperature. With the decrease of temperature, the solid solubility of hydrogen in zirconium gradually decreases, which is conducive to the nucleation and growth of hydride. This unique growth process also poses a challenge for the in-situ study of zirconium hydride. Recently, the research group of Professor hanweizhong from the school of materials, Xi'an Jiaotong University found that electron beam irradiation can induce the nucleation and growth of hydride in zirconium at room temperature, which provides a simple and easy new method for in-situ study of the phase transition process of zirconium hydride. Based on this method, the whole process of hydride nucleation and precipitation was systematically studied by the research group using transmission electron microscope. Hydride precipitation includes two steps: dislocation emission and hydride growth. In the study, the phase transition process of zirconium hydride is slowed down by reducing the hydrogen concentration (zirconium absorbs a small amount of hydrogen in the double jet process). Using a high-resolution camera, it is captured that dislocation emission and hydride growth are an alternating process, such as dislocation emission hydride growth dislocation re emission hydride re growth (Fig. 1), rather than a synchronous process. High resolution electron microscope observation found that there were uneven steps at the interface between the hydride front and the matrix, which provided favorable conditions for dislocation emission at the hydride front (Fig. 2).

Density functional theory calculations show that the hydride phase transition produces tensile stress in the zirconium matrix and compressive stress in the hydride. The tensile stress produced by the volume expansion of zirconium hydride phase transition is enough to stimulate the dislocation slip of the cylinder, cone and base plane in zirconium, which makes it possible to form a complex dislocation structure around the hydride (Fig. 2). Through the calculation and analysis of free energy, it is found that the volume expansion caused by hydride phase transition forms compressive stress, which is not conducive to the continuous precipitation and growth of hydride. When the hydride phase changes, the tensile stress inside the matrix increases the solid solubility of hydrogen at the front of the hydride interface, and the driving force of phase change decreases. When the dislocation is emitted from the hydride front, the tensile stress of the surrounding matrix decreases, and the solid solubility of hydrogen at the interface front decreases, reaching the hydrogen supersaturation state, which promotes the further precipitation of hydride. In addition, dislocation emission can increase the concentration gradient of hydrogen between the hydride front and the zirconium matrix, accelerate the precipitation rate of zirconium hydride, and promote the growth of hydride (Fig. 3).