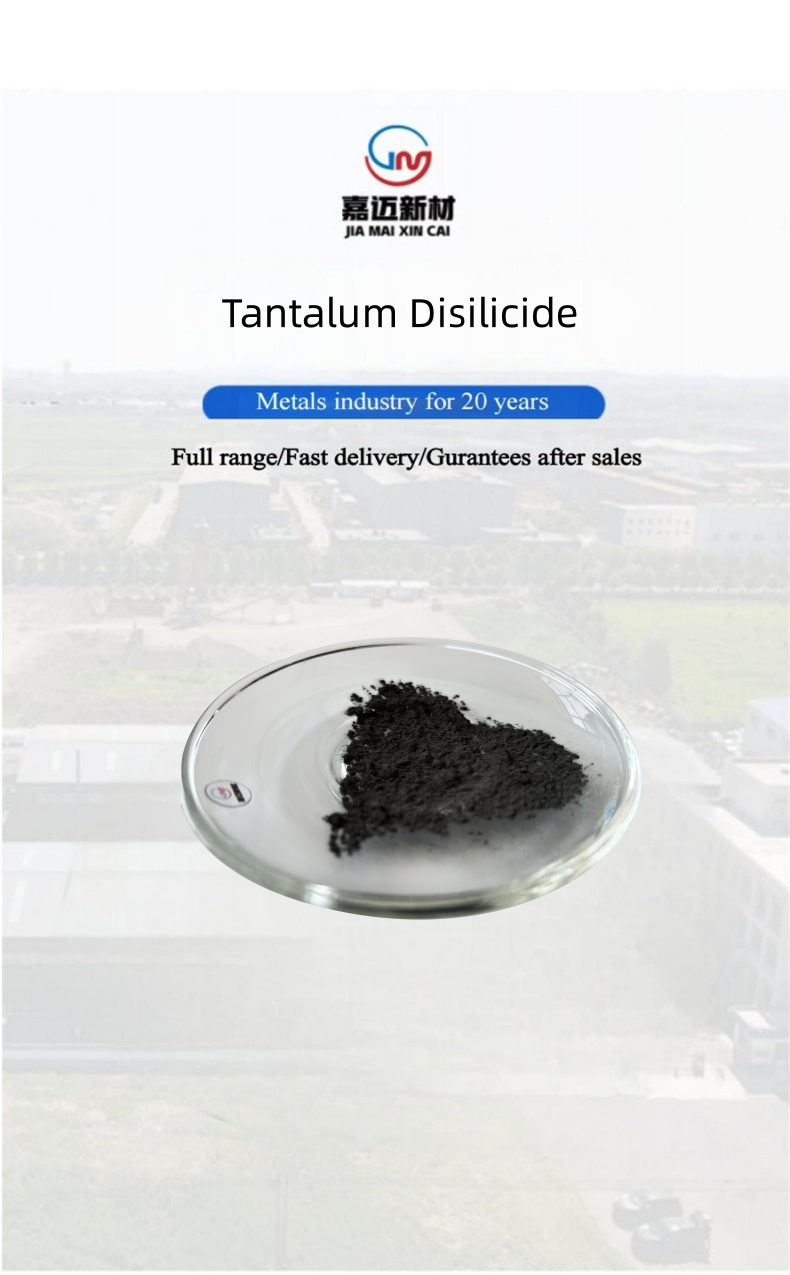

Product Name: Tantalum Disilicide (TaSi2)

Specification: 0.8-10um (D50)

Appearance: Irregular

Color: Black Grey

Features: high hardness, high melting point, oxidation resistance, and excellent thermal and electrical conductivity

Application: Integrated circuits, aerospace, engines and other fields

tantalum silicide

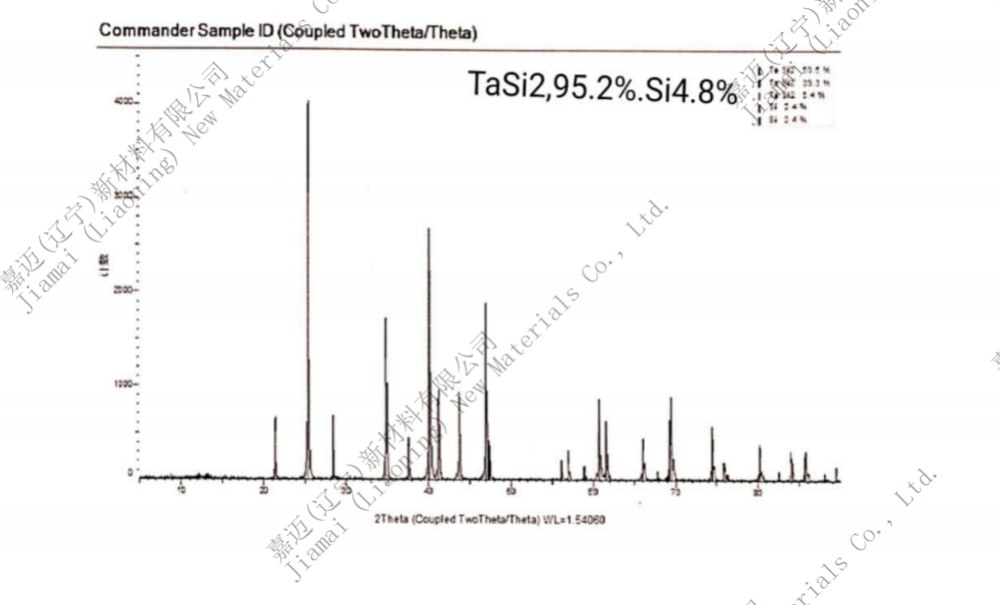

Chemical formula: TaSi2

Cas:12067-56-0

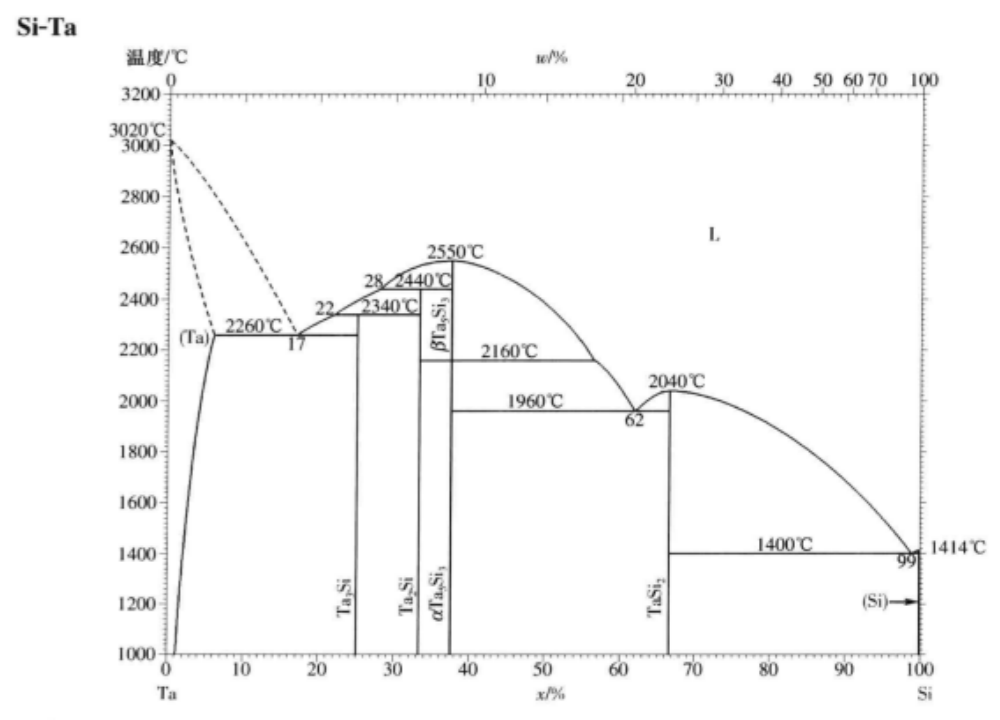

Melting point: 2200 ℃

Density: 9,14 g/cm3

Color: Grey Black

Resistance: 8.5 (ρ/μ Ω. cm)

Preparation of Tantalum Silicide:

Using tantalum metal and silicon powder as raw materials, they are crushed and mixed evenly. Then, they are placed in a graphite furnace and heated to 1100-1500 ℃ for pre reaction. Hydrogen gas is then introduced and heated to 800 ℃ for reaction, resulting in tantalum silicide. Alternatively, tantalum hydride can be obtained by reducing tantalum pentoxide with calcium hydride, followed by heating to 1800 ℃ to obtain metallic tantalum, and then adding silicon powder to synthesize tantalum silicide.

The main applications of tantalum silicide include the following aspects:

1) Electric heating element: Tantalum silicide has a high melting point and low resistivity, making it suitable for making electric heating elements that can efficiently convert electrical energy into thermal energy.

2) High temperature structural components: Due to its excellent resistance to high temperature oxidation and good compatibility, tantalum silicide is often used to manufacture high-temperature structural components, such as high-temperature anti-oxidation coatings and metal ceramics.

3) Integrated circuit: In integrated circuits, tantalum silicide is used to connect circuits and has good electrical performance and stability.

4) Aerospace: Tantalum silicide has a wide range of applications in the aerospace industry, such as high-temperature structural materials and anti-oxidation coatings, which can withstand extreme high-temperature environments.

5) Engine: Due to its excellent high-temperature oxidation resistance and mechanical properties, tantalum silicide is also used for high-temperature components of engines.

Packaging and storage: This product is packaged in an inert gas filled plastic bag, sealed and stored in a dry and cool environment. It should not be exposed to air to prevent moisture from causing oxidation and aggregation, which may affect dispersion performance and usage effectiveness; The packaging quantity can be provided in separate packages according to customer requirements.