Titanium Nitride Powder(TiN)

![]()

![]()

![]()

![]()

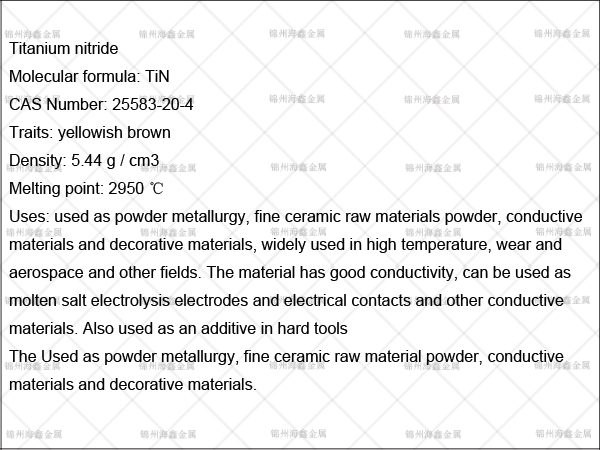

Name: Titanium Nitride

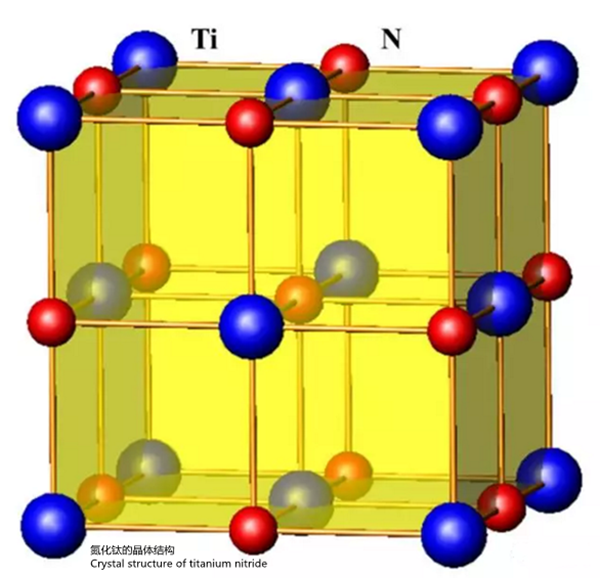

Appearance: The powder is generally yellow brown, ultrafine titanium nitride powder is black, and titanium nitride crystals are yellow with metallic luster.

Melting point: 2930 ℃

Density: 5.43-5.44g/cm3

Microhardness: 2160kg/mm2

Mohs hardness: 8-9

Coefficient of thermal expansion: 6.81 * 10-6/℃ (room temperature)

Thermal conductivity: 29.31W/(m * K) (room temperature)

Resistivity: 22 * 10-6 Ω * cm (room temperature)

Molecular weight: 61.89

Chemical properties: titanium nitride has high chemical stability. In general, it does not react with water, steam, hydrochloric acid, sulfuric acid, etc., but has a certain solubility in hydrofluoric acid. If hydrofluoric acid coexists with oxidants such as HF+HNO3, HF+KMnO4, etc., titanium nitride can be completely dissolved. In a strong alkaline solution, titanium nitride decomposes to release ammonia gas.

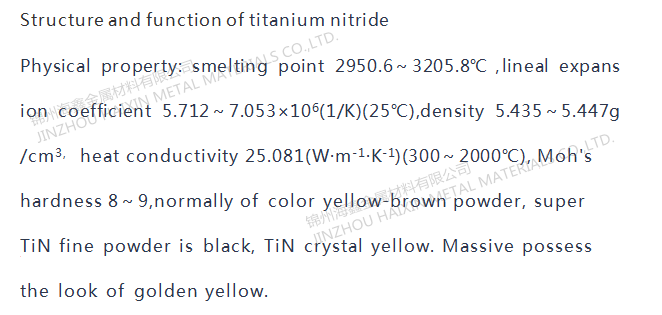

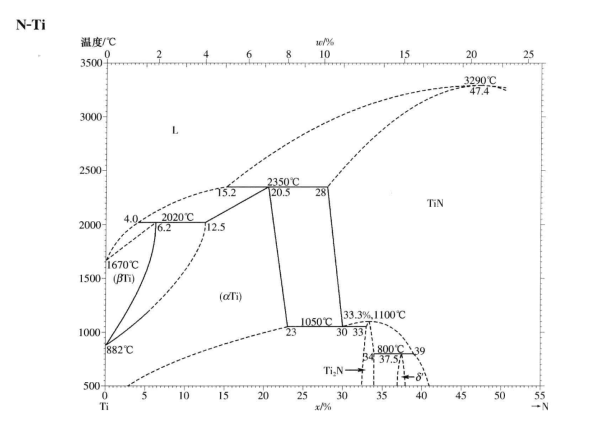

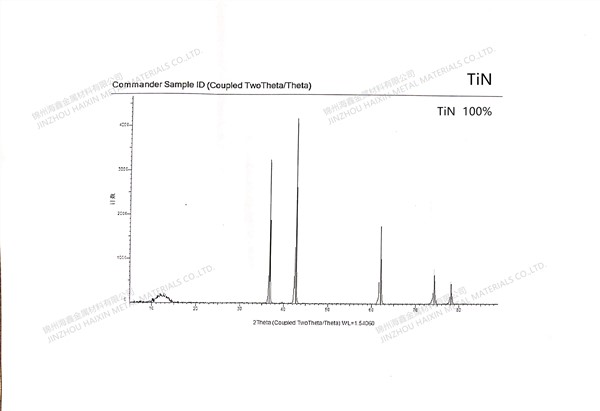

TiN has a typical NaCl type structure, belonging to a face centered cubic lattice. The top of the face centered cubic is a nitrogen atom, and the titanium atom is located in the (1/2,0,0) spatial position of the face centered cubic. TiN is a non stoichiometric compound with a stable composition range of TiN0.6 to TiN1.16. The nitrogen content can vary within a certain range without causing changes in the TiN structure. TiN powder is generally yellow brown, ultrafine TiN powder is black, and TiN crystals are golden yellow. The lattice constant of TiN is a=4.23 nm, the lattice constant of TiC is a=4.238 nm, and the lattice constant of TiO is a=4.15 nm. The lattice parameters of these three substances are very close, so the nitrogen atoms in the TiN molecule can be replaced by oxygen and carbon atoms in any ratio to form a solid solution. The physical and chemical properties of titanium nitride are determined by the content of nitrogen element. When the content of nitrogen element decreases, the lattice parameters of titanium nitride will increase instead, and the hardness will also increase microscopically, But the seismic resistance of titanium nitride decreases accordingly.

Synthesis method:

(1) Direct Nitridation of Titanium Powder or TiH2

Titanium powder is nitrided under nitrogen or hydrogen atmosphere at 1273-1673K for 1-4 hours, and the product is crushed and repeated several times to obtain stoichiometric titanium nitride powder. The equation is:

2Ti+N2=2TiN

It can also be nitrided with metal hydride TiH2, which can react below 1273K, and the equation is:

2TiH2+N2=2TiN+2H2

The advantage of this method is that it is easy to operate and can obtain high-quality titanium nitride powder. However, the disadvantage is that the raw material price is too high to produce in bulk, and this process is prone to powder sintering, resulting in losses.

(2) TiO2 carbothermal reduction nitridation method

The carbon thermal reduction nitridation method of TiO2 uses TiO2 as the raw material, carbon graphite as the reducing agent, and reacts with N2 to generate TiN. The synthesis temperature is 1380-1800 ℃, and the reaction time is about 15 hours. In this reaction environment, carbon not only reacts with oxygen, but also reacts with titanium to generate TiC. Because the lattice of titanium carbide, titanium nitride and titanium oxide are very close, they are easy to generate a solid solution.

The purity of TiN obtained by this method is generally not high, and the content of O and C is relatively high. In order to obtain TiN with low O and C content, higher reaction temperature and longer reaction time are required.

In addition, some experts also adopt another method, which is to mix magnesium powder and titanium oxide under low temperature conditions in a certain proportion to produce titanium nitride.

(3) Microwave carbothermal reduction method

The microwave carbothermal reduction method is an oxidation-reduction reaction carried out at higher temperatures using inorganic carbon as a reducing agent. Liu Binghai and others in China used this method to prepare titanium nitride powder. The specific operation is as follows: titanium oxide is used as the raw material, and carbon is heated by microwave until the temperature reaches 1200 ℃. At this temperature, the reduction reaction is maintained for 1 hour to obtain titanium nitride powder.

The titanium nitride powder prepared by this method has higher purity compared to conventional methods, and has advantages such as low synthesis temperature (reduced by 100-200 ℃ compared to the original method) and short cycle time (1/15 of the conventional method).

(4) Chemical vapor deposition method

The chemical vapor deposition method uses gaseous TiCl4 as the raw material, H2 as the reducing agent, and N2 to generate TiN, with a synthesis temperature of 1100~1500 ℃. This process is commonly used for coatings on metal and ceramic surfaces to enhance the hardness and wear resistance of ceramics and metals.

This synthesized TiN has high purity, but low production efficiency and high cost. This process is a commonly used method for coating TiN films on the surfaces of metals, ceramics, and other items to make them aesthetically pleasing

(5) Self propagating high-temperature synthesis method

Self propagating high-temperature synthesis method is also known as combustion synthesis method. This method involves igniting titanium powder (in the form of a billet) directly in nitrogen gas (with a certain pressure limit), and burning the titanium powder in nitrogen gas to obtain TiN products. This process has been widely studied and commercialized in Russia, the United States, and Japan.

In domestic research reports on this aspect, Wang Weimin et al. used this process to prepare TiN ceramic powder and studied the effects of process parameters such as compactor density, diluent, and nitrogen partial pressure on the synthesis. Liu Suying and others have also studied this process.

(6) Mechanical alloying method

The mechanical alloying method involves placing titanium powder in a system of ammonia or nitrogen gas, and using a high-energy ball mill to make them interact with each other under strong collision and agitation of the grinding balls to obtain nano titanium nitride. This is a novel synthesis method. In China, Liu Zhijian et al. used TiH1.924 powder instead of Ti powder to react with nitrogen. Using this high-energy ball milling process, after 100 hours of high-energy ball milling in flowing ammonia, almost all TiH1.924 was converted to TiN, and the conversion rate was greatly improved. And Zhou Li and others later prepared nano titanium nitride powder using the same method, with a reaction time of only 9 hours.

(7) Molten salt synthesis method

There are no relevant reports on the use of molten salt synthesis method in the preparation of titanium nitride, but studying this method for the preparation of titanium nitride is a good research direction. This method uses low melting point molten salt as the reaction medium, and the reactants can be dissolved in the molten salt. The entire reaction is completed in an atomic level environment. After the reaction is completed, the salt is dissolved and filtered with a suitable solvent to obtain the product.

The product obtained by this method has high purity, simple operation, short reaction time, and no strict requirements for reaction temperature. The morphology and particle size of the product are easy to control, and there is no agglomeration phenomenon.

(8) Sol gel method

The sol gel method is to mix the reactants evenly in the liquid phase, and then carry out the hydrolysis and condensation process. The reactants will form a transparent sol in the solution. This sol will form a gel after aging and slow polymerization. The gel will be dried and solidified to get the materials we need.

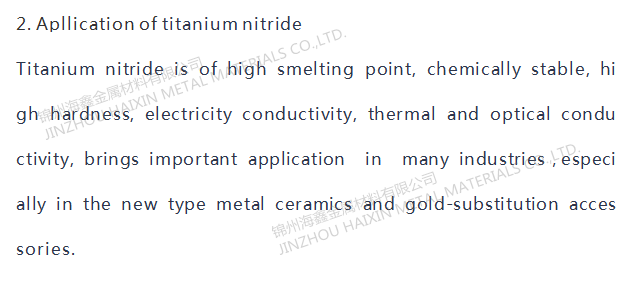

Application field:

(1) Titanium nitride has high biocompatibility and can be applied in clinical medicine and dentistry. This material is non-toxic and complies with FDA specifications, so it is also commonly used in medical devices, such as maintaining the edge sharpness of the scalpel blade and orthopedic bone saw blade, or directly used as implant prosthesis (especially hip replacement implant) and other medical implants.

(2) Titanium nitride has a low friction coefficient and can be used as a high-temperature lubricant. This coating is also used in aerospace and military applications, as well as to protect the sliding surfaces of suspension devices for bicycles and motorcycles, and even the shock absorption shafts of remote-controlled toy cars.

(3) Titanium nitride has a metallic luster and can be used as a simulated gold decorative material, with good application prospects in the gold substitute decoration industry; Titanium nitride can also be used as a gold coating in the jewelry industry; It can be used as a potential material to replace WC, greatly reducing the application cost of the material.

(4) It has super strong hardness and wear resistance, and can be used to develop new types of tools. This new type of tool has significantly improved durability and service life compared to ordinary hard alloy tools. Titanium nitride coatings are widely used on metal edges to maintain the corrosion resistance of mechanical molds, such as drills and milling cutters, often improving their lifespan by increasing three or more factors.

(5) Titanium nitride is a new type of multifunctional ceramic material. Adding a certain amount of titanium nitride to TiC-Mo-Ni series cermets can significantly refine the hard phase grains, thereby greatly improving the physical properties of the ceramics, both at room temperature and under high temperature conditions, thereby greatly improving the high-temperature corrosion resistance and oxidation resistance of the cermets; Adding TiN powder to ceramics in a certain proportion can enhance the strength, toughness, and hardness of ceramics; Adding nano titanium nitride to TiN/Al2O3 composite nanoceramics, and mixing them evenly through various methods (such as mechanical mixing), the ceramic material containing nano titanium nitride particles forms a conductive network inside. This material can be used as an electronic component in the semiconductor industry.

(6) Adding a certain amount of TiN to magnesia carbon bricks can greatly improve their slag corrosion resistance.

(7) Titanium nitride is an excellent structural material that can be used in jet thrusters and rockets. Titanium nitride alloy is also commonly used in the fields of bearings and sealing rings, highlighting the excellent application effect of titanium nitride.

(8) Based on the excellent conductivity of titanium nitride, it can be made into various materials such as electrodes and point contacts.

(9) Titanium nitride has a high superconducting critical temperature and can be used as an excellent superconducting material.

(10) Titanium nitride has a melting point higher than most transition metal nitrides and a density lower than most metal nitrides, making it a unique refractory material.

(11) Glass coated with titanium nitride film is still a new type of "thermal mirror material". When the thickness of the film is greater than 90nm, the infrared reflectance is greater than 75%, improving the insulation performance of the glass. The color of the titanium nitride film can also be adjusted freely. As the nitrogen content decreases, the film will appear in colors such as gold, bronze, and pink, making it very beautiful. At present, the demand for titanium nitride powder has sharply increased due to the development of nitrogen-containing metal ceramic tools; Moreover, the development of gold substitute decoration technology is quite rapid internationally, and the application of titanium nitride in this field has very broad prospects. Titanium nitride can be coated on glass as a film. When the infrared reflectance is greater than 75% and the thickness of the titanium nitride film is greater than 90nm, it can effectively improve the insulation performance of the glass. In addition, adjusting the percentage content of nitrogen elements in titanium nitride can change the color of the titanium nitride film, thereby achieving ideal aesthetic effects. Titanium nitride (TiN) is a relatively stable compound that does not react with metals such as iron, chromium, calcium, and magnesium at high temperatures. TiN crucibles also do not react with acidic or alkaline slag in CO and N2 atmospheres. Therefore, TiN crucibles are excellent containers for studying the interaction between molten steel and some elements. TiN loses nitrogen when heated in vacuum, generating titanium nitride with lower nitrogen content.

(12) Titanium nitride thin film can be used in the field of microelectronics as a conductive barrier layer between active devices and metal contacts. And when the thin film is diffused into metal silicon, its conductivity (30-70 μ Ω · cm) is sufficient to form a good conductive connection.

TiN has attractive golden yellow, high melting point, high hardness, good chemical stability, small wetting with metals, and high conductivity and superconductivity,

It can be applied to high-temperature structural materials and superconducting materials. Titanium nitride is a new type of multifunctional cermet material with high melting point, high hardness, and low friction coefficient. It is a good conductor of heat and electricity. Firstly, titanium nitride is an excellent structural material used in high-strength metal ceramic tools, jet thrusters, and rockets. In addition, titanium nitride has a lower friction coefficient and can be used as a high-temperature lubricant. Titanium nitride alloy can exhibit excellent performance as a bearing and sealing ring. Titanium nitride has high conductivity and can be used as electrodes for molten salt electrolysis, as well as materials such as point contacts and thin film resistors. Titanium nitride has a high superconducting critical temperature and is an excellent superconducting material. It is particularly noteworthy that the titanium nitride coating and its sintered body have a satisfactory golden yellow color, which can be used as a substitute for gold decoration materials with good imitation gold effect, decorative value, and anti-corrosion, extending the lifespan of handicrafts. At present, due to the development of nitrogen-containing metal ceramic tools, the demand for titanium nitride powder has sharply increased, and the development of gold substitute decoration technology is quite fast internationally. The application of titanium nitride in this field has very broad prospects. Not only is titanium nitride coating cheap, but it also outperforms vacuum coating in terms of corrosion resistance, friction resistance, and other properties.

![]()