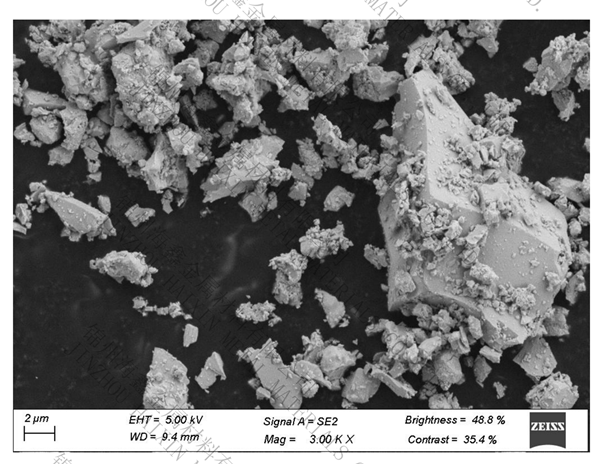

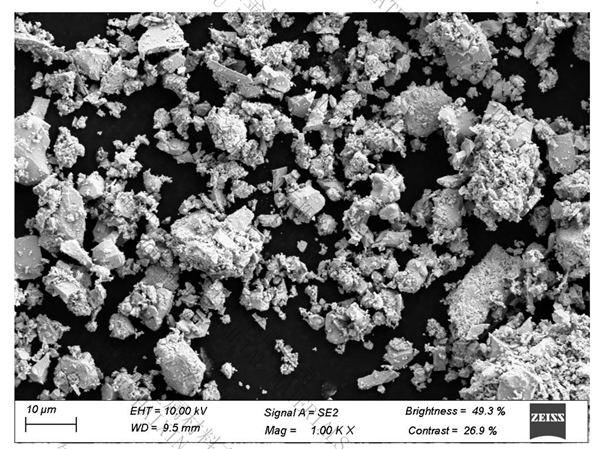

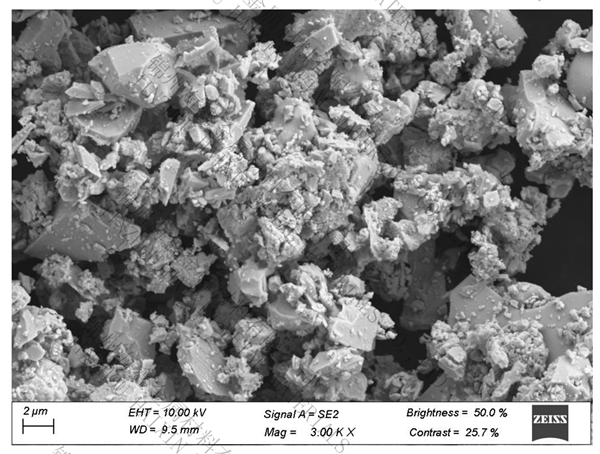

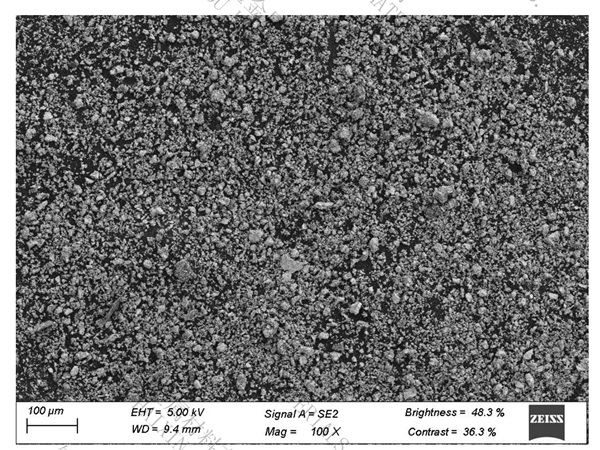

Hafnium Carbide Powder(HfC)

.jpg)

.jpg)

Chinese name: hafnium carbide

Molecular formula: HfC

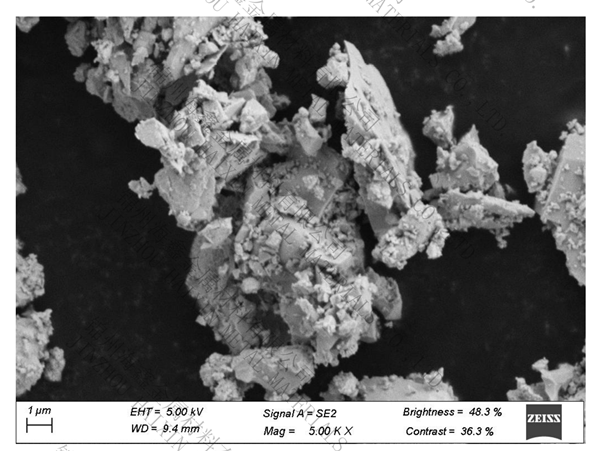

Appearance: grayish black powder

CAS:12069-85-1

EINECS:235-114-1

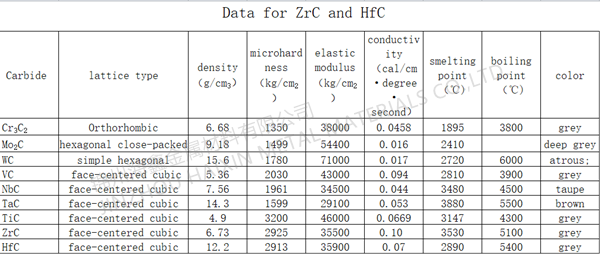

Molecular weight: 190.5325

Melting point: 3890 ℃

Theoretical density: 12.7g/cm3

Thermal conductivity: 6.28 [W (m · K) - 1] (20 ℃)

Volume resistivity: 1.95 × 10-4Ω·cm(2900℃)

Thermal expansion coefficient: 6.73 × 10-6/℃

Resistivity: 40-50/ μ Ω·cm,

Elastic modulus: 35.9 × 103MPa

Compressive strength: 1380MPa

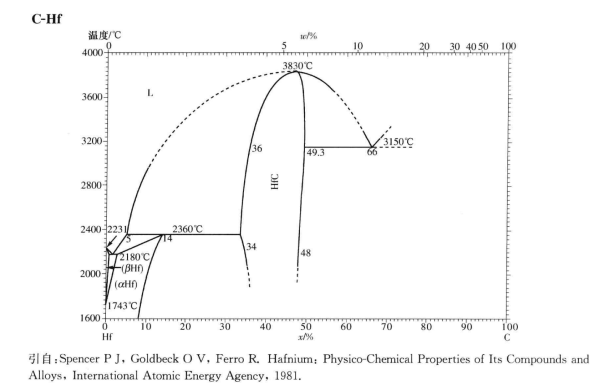

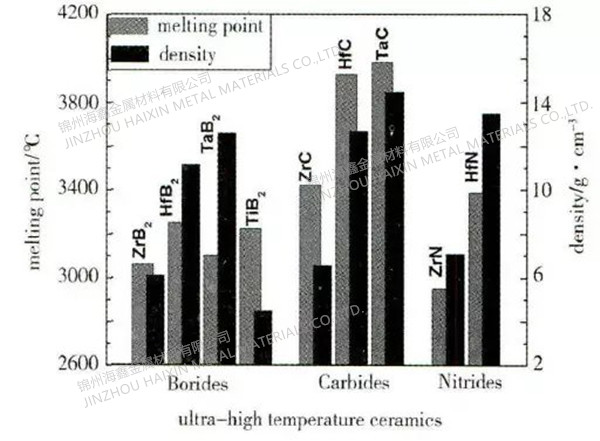

Properties: Hafnium carbide is an inorganic substance, which is soluble in hydrofluoric acid, hot concentrated sulfuric acid and nitric acid. It belongs to non-metallic carbide, and its structure is NaCl type face centered cubic structure, which is a metastable structure. This non stoichiometric carbide shows the existence of free carbon, namely HfCx (0.5 < x < 1), in which Hf atoms form a compact cubic lattice, and C atoms are in the octahedral gap position of the lattice. In compounds with such structures, there are metal bonds and covalent bonds at the same time, and the bonding between atoms is particularly strong. Because the covalent bond energy of C-Hf is large, it is very difficult to destroy its structure. Therefore, it shows the characteristics of ultra-high hardness on the macro level. Its Mohs hardness is 9, second only to diamond. Because the highly symmetric atomic bonds must be broken when HfC crystal melts, however, it is extremely difficult to break this bond. The bond energy of the atomic bonds of hafnium carbide is as high as EA=87.2163KJ/mol, which shows the characteristics of ultra-high melting point on the macro level, and the melting point of hafnium carbide is as high as 3890 ℃. Therefore, they often have excellent properties such as high strength, high hardness and high melting point.

Preparation methods: direct carbonization method, magnesium thermal reduction method, carbothermal reduction method, liquid precursor conversion method, chemical vapor deposition method, sol gel method, spark plasma sintering method, etc. Generally, hafnium dioxide and carbon are used to synthesize powder in inert or reducing atmosphere, with reaction temperature of 1900-2300 ℃.

Purpose:

1) Hafnium carbide can be used as additive and deoxidizer in steel making industry, which can greatly improve steel quality.

2) Hafnium carbide can be used as the lining of high melting point metal melting crucible, and also can be used as the coating material for cutting tools.

3) Hafnium carbide is an important functional material for making control rods and protective devices of nuclear reactors, and is an important material in the atomic energy industry.

4) Hafnium carbide can be used in electronic and optical fields, as thermooptic irradiators, field emitters, etc. It is a cathode material for manufacturing X-ray tubes and microwave tubes in the electrical industry.

5) Hafnium carbide can be used as the thruster of rocket, for rocket nozzle, rocket nozzle and rocket nose cone, and the alloy containing hafnium carbide can be used as the front protective layer of rocket nozzle and glider aircraft.

Product application cases:

1. HfC hafnium carbide powder material added to solid rocket motor throat lining material as an additive is a solid rocket motor nozzle throat lining material due to its superior high-temperature thermophysical and mechanical properties compared with other materials. In the process of engine operation, the carbon/carbon composite throat lining will be damaged due to the heat flow erosion and ablation of the internal surface with high temperature, high pressure, high speed and corrosive particles under the harsh thermal environment, which shows that the throat diameter is enlarged, the surface is rough and uneven, and the profile is irregular, thus affecting the working pressure of the engine and reducing the nozzle efficiency. The ablation resistance of HfC-C/C composites can be greatly improved when 8% - 10% HfC hafnium carbide powder is added to the carbon matrix of nozzle throat liner of a certain weapon system. HfC hafnium carbide powder material contributes to the ablation resistance of HfC-C/C composite throat liner in two aspects:

(1) At the ablation temperature of 3500 ℃, HfC hafnium carbide powder materials preferentially react with oxygen to form HfO2 in the high-temperature ablation process, which effectively prevents the oxidation of carbon matrix and carbon fiber in the composite materials by oxygen atmosphere;

(2) As HfC hafnium carbide powder material has high strength and hardness, it also effectively improves the overall mechanical abrasion resistance and erosion resistance of the material, so that the mechanical denudation of the inner surface of the throat liner by gas can be effectively suppressed. Obviously, the ablation resistance of HfC-C/C composite increases with the increase of HfC content. The experimental results show that when the HfC content reaches 8% - 10%, the linear ablation rate of HfC-C/C composite throat liner will appear approximately constant and stable ablation stage. Under the test conditions of solid rocket motor, the overall HfC-C/C composite throat liner has good ablation resistance.

2. One atom of hafnium carbide and four atom of tantalum carbide, the compound carbide 4TaC · HfC of tantalum carbide and hafnium carbide, is used to test the heat resistance of 4TaC · HfC by using laser heating technology. The melting point reaches 4215 ℃. It is a kind of composite material compound and refractory ceramic material with high melting point. A research institute in the United States has applied it to the thermal protection system of high-speed aircraft. It has strong resistance to heat, can withstand and resist the harsh high temperature environment, and can also be used as the fuel cladding in the overheated environment of nuclear reactors. The heat caused by air friction includes very high temperatures when traveling at supersonic speeds above Mach 5. As the 4TaC · HfC material can withstand and resist the harsh high temperature environment, it paves the way for the development of the next generation of supersonic aircraft. This material means that the new spacecraft may have a faster speed than before. 4TaC · HfC materials are used in supersonic aircraft, aircraft nose, and the edges of external components that must bear heavy friction during flight, making it possible for aircraft traveling at speeds above Mach 5 to carry people.

3. HfC hafnium carbide powder material is an important functional material for making control rods and protective devices of atomic nuclear reactors. It is an important material in the atomic energy industry and can be used as a rocket thruster, especially in the field of rocket nozzles, throat materials of rocket nozzles, and nose cones of re-entry space rockets. The alloy containing hafnium carbide can be used as the front protective layer for rocket nozzles and glide reentry vehicles.

4. HfC hafnium carbide powder material, due to its high hardness and melting point, is used as an additive in carbide cutting tools, metal ceramic cutting tools, powder metallurgy products, high-temperature structural parts materials, and high-temperature resistant spraying materials; Hf Ta alloy added with hafnium carbide can be used to manufacture tool steel and resistance materials; Adding hafnium carbide to heat-resistant alloys, such as tungsten, molybdenum and tantalum, can improve the hardness, strength, ablation resistance and high temperature resistance of materials;

5. Due to its high melting point, HfC hafnium carbide powder can be used as a deoxidizer in steelmaking industry as an additive, which can greatly improve the quality of steel products; In the electrical industry, it is the cathode material for manufacturing X-ray tubes and microwave tubes.