Vanadium Carbide Powder(VC)

.jpg)

.jpg)

.jpg)

Chinese name: vanadium carbide

Molecular formula: VC

English name: Vanadium carbide

CAS:12070-10-9

EINECS:235-122-5

Molecular weight: 62.95

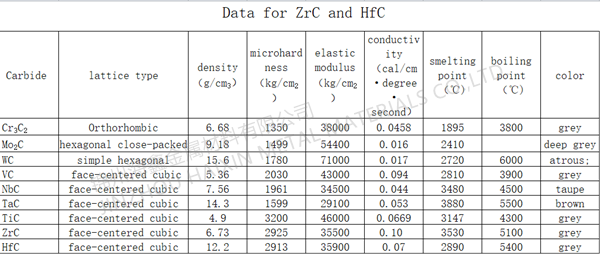

Melting point: 2810 ℃

Boiling point: 3900 ℃

Relative density: 5.77

Hardness range: 9 to 9.5 Mohs

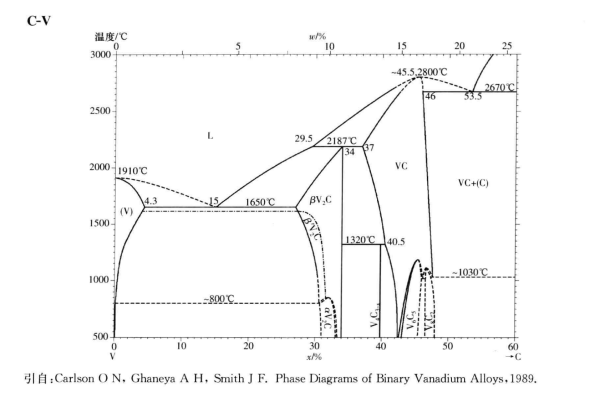

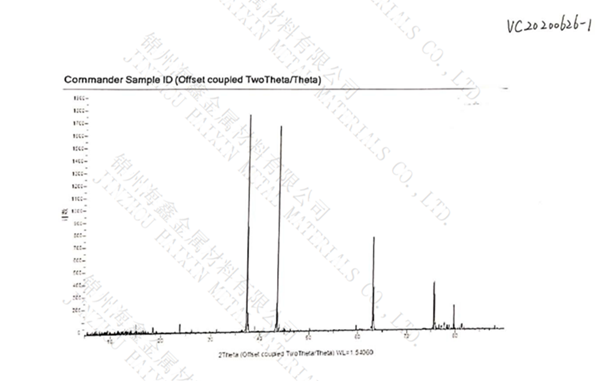

Properties: black cubic crystal, containing 19.08% carbon, belongs to sodium chloride cubic crystal system, gray metallic powder. It is insoluble in water, nitric acid, cold water, hydrochloric acid and sulfuric acid. It can be melted with potassium nitrate, with stable chemical properties and chemical corrosion resistance. It has excellent physical and chemical properties, such as high melting point, good conductivity, good chemical corrosion resistance, etc.

Product application:

1. As a grain growth inhibitor, vanadium carbide has been widely used in the preparation of ultra-fine cemented carbides. The mechanism is that the grain growth mainly occurs in the dissolution and precipitation process of WC. WC dissolves in the liquid phase and precipitates on larger WC crystals. Inhibitors change the interface free energy of WC Co, thus restricting the dissolution precipitation process, reducing the dissolution precipitation rate, and slowing down the process of grain growth. It is reported that the life of cemented carbide can be increased by 20% by adding VC, but its mechanism is still unclear. Because of the high activity of superfine VC, fast atomic migration speed, it is more conducive to particle diffusion and easier to dissolve in the cobalt phase, thus effectively preventing the dissolution precipitation of tungsten carbide. Therefore, ultrafine VC is of great significance to the development of ultrafine cemented carbide. Vanadium carbide has the general characteristics of transition metal carbides, such as high hardness, melting point and high temperature strength, as well as good electrical and thermal conductivity. Therefore, it is widely used in iron and steel metallurgy, cemented carbide, electronic products, catalysts and high-temperature coating materials. Among them, the addition of vanadium carbide in steel can improve the comprehensive properties of steel, such as wear resistance, corrosion resistance, toughness, strength, ductility, hardness and thermal fatigue resistance, and make the steel have strong weldability, and can play a role in eliminating inclusions, and can be used as wear-resistant materials in different cutting and wear-resistant tools.

2. Vanadium carbide is used in WC Ni cemented carbide. Adding a small amount of vanadium carbide can effectively reduce the Curie point of the alloy and make the alloy change from ferromagnetism to paramagnetism at room temperature. The addition of VC can reduce the saturation magnetization, remanence, coercive force, magnetic energy product, permeability and Curie temperature of WC-10% Ni cemented carbide, and produce a non-magnetic alloy. The mechanism is that the solid solution of VC in the bonding phase increases the atomic spacing a of the Ni lattice, thus increasing the ratio of a to the radius r of the unfilled electronic layer of Ni, which makes the alloy change from magnetic to nonmagnetic.

3. The solid solution formed by vanadium carbide and other metal carbides is used as a matrix or additive in the production of tungsten free cemented carbides. If appropriate amount of vanadium carbide is added, the wear resistance, high temperature strength and high temperature oxidation resistance of TiB2-Fe Mo cemented carbide can be improved.

4. Vanadium carbide can be used as an effective catalyst. Because of its high activity, selectivity, stability and the ability to resist catalyst poisoning in hydrocarbon reactions, it has been widely used as a new catalyst. For example, synthesis of NH3.

5. The main reason why high vanadium high-speed steel has excellent wear resistance and safety is that it forms high hardness vanadium carbide by increasing the content of vanadium in it. High vanadium high speed steel, a new kind of steel, is used in the development direction of new wear-resistant materials. Its service life is 3 times as long as that of high chromium cast iron and 10 times as long as that of high manganese steel.

6. Vanadium carbide has good morphology (less splitting on the matrix) and high hardness (the microhardness of vanadium carbide can reach HV2600), which can make high vanadium ferrocarbon alloy show excellent wear resistance.

7. Recently, a new method has been developed abroad to combine the thin layer of vanadium carbide on the tool surface by metallurgy. The efficiency of machining parts with this tool can be improved several times, even dozens of times. In this method, the tool steel cutter is placed in a borate bath containing carbide elements, so that vanadium heat can diffuse into the tool steel matrix and be combined with carbon. The common base materials are Cr5MoLV and Cr12MoV alloy tool steels. The hardness of this coating is as high as 3200~3800HV, and it is not easy to peel off. 20% of the coating thickness (0.014~0.0125mm) penetrates into the tool surface, so the tool life can be greatly improved.

8. It can be used as raw material for extracting metal pure vanadium.

Packaging and storage: The product is packed in inert gas filled plastic bags, sealed and stored in a dry and cool environment. It should not be exposed to the air to prevent moisture and oxidation agglomeration, which will affect the dispersion performance and use effect; The number of packages can be provided according to the customer's requirements.