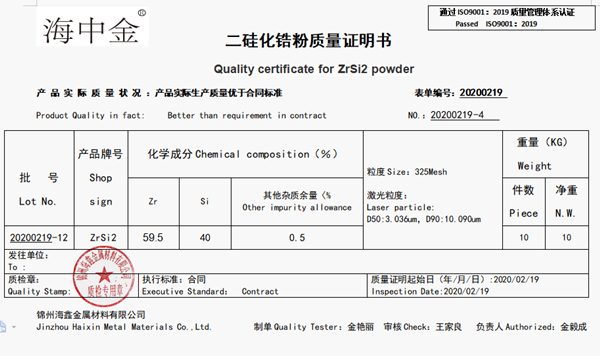

Zirconium silicide(ZrSi2)

Zirconium silicide

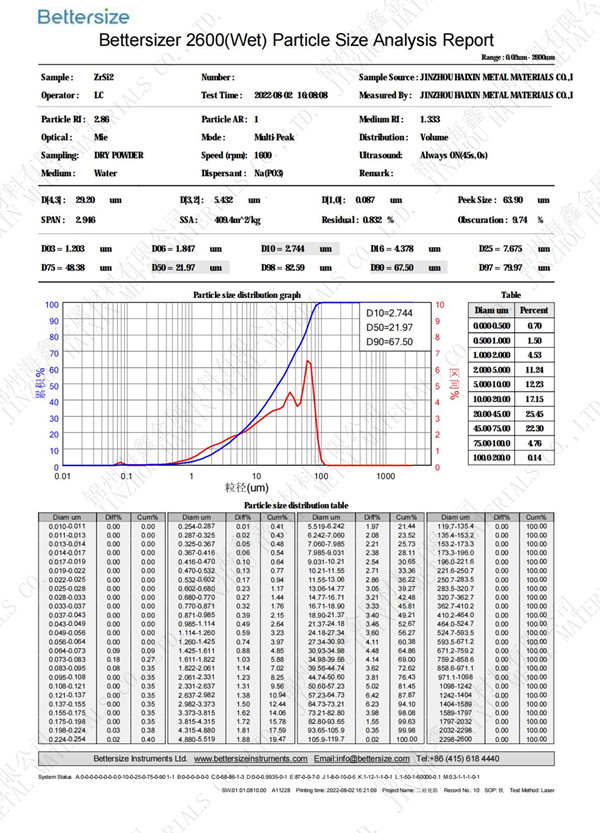

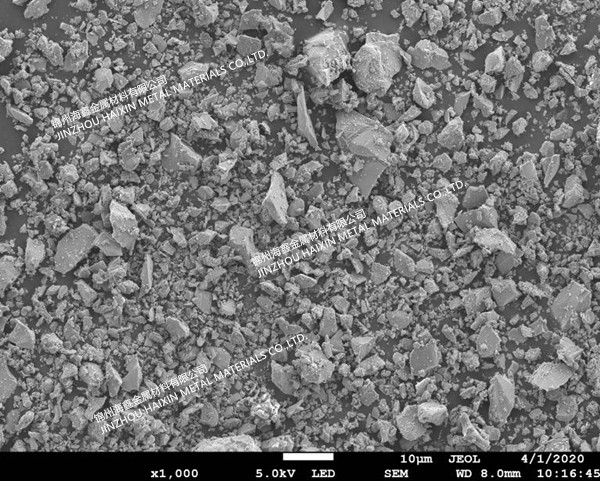

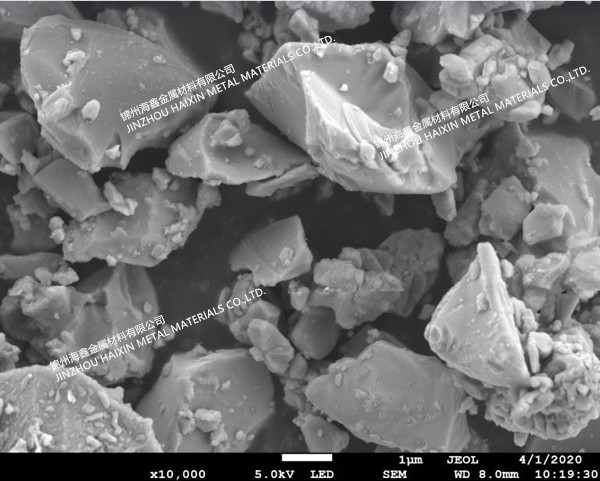

Character: gray square crystal powder

Density (g / ml, 25 ℃): 4.88

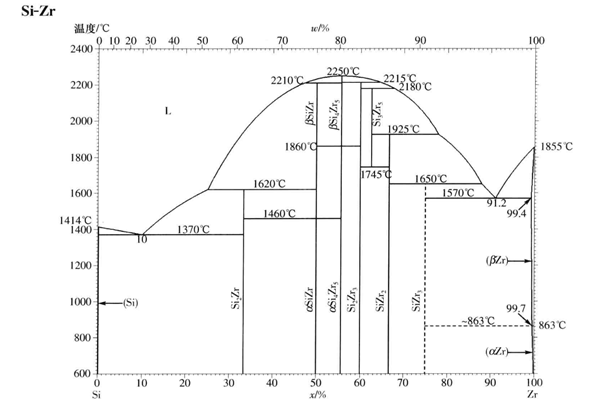

Melting point (OC): 1620

Lattice constant: a = 0.372nm, B = 1.476nm, C = 0.367nm.

Microhardness (kg / mm2): 1063

Heat of formation (kJ / mol): 62.8

Properties: zirconium silicide or zirconium disilicide, chemical formula: zrsi2, is a steel gray rhombic luster crystal with a relative density of 4.8822. Zirconium silicide is insoluble in water, inorganic acid and aqua regia, but soluble in hydrofluoric acid. Zirconium silicide is a steel gray rhombic lustrous crystal with a relative density of 4.8822.

Preparation process of zirconium silicide:

1. Taking metal zirconium and silicon powder as raw materials, the metal zirconium is crushed, and then mixed with silicon powder. The mixture is put into a graphite furnace, heated to 900-1000 ℃ for pre reaction, then hydrogen is introduced, and then heated to about 1200 ℃ for reaction to prepare zirconium silicide.

2. Zirconium silicide is prepared by direct method with metal zirconium and silicon powder as raw materials. The reaction formula is as follows: first, the metal zirconium is crushed, then it is fully mixed with silicon powder, the mixture is put into a graphite furnace, heated to 900-1000 ℃ for pre reaction, then hydrogen is introduced, and then heated to about 1200 ℃ for homogenization reaction, that is, zirconium silicide is prepared.

3. A method for preparing zirconium silicide nanomaterials, comprising the following steps: (1) 5mmol zirconium dioxide, 5mmol silicon powder and 50mmol metal lithium are added to a 20ml stainless steel autoclave and sealed, and then the autoclave is put into an electric furnace capable of programmed temperature rise, the temperature rise rate of the electric furnace is set to 10 ° C / min, the electric furnace is heated to 600 ° C, and the reaction is maintained for 40 hours after the heating is completed, and the reaction is naturally cooled to room temperature after the reaction, Then the autoclave was opened to take out the product (black deposit of chemicalbook); (2) The reaction products were washed once with distilled water, then washed once with dilute hydrochloric acid and absolute ethanol respectively, filtered the washed products, and then dried in a vacuum drying oven at 60 ℃ for 4 hours to obtain zirconium silicide nanomaterials. According to the quality of the prepared zirconium silicide nanomaterials and the quality of the raw material zirconium dioxide, the yield of zirconium silicide was 85%. The above reaction process is as follows: ZrO2 + Si + 4li = zrsi + 2li2o

Application of zirconium silicide:

1. Zrsi2 is a zirconium silicon intermetallic compound. It is a ceramic material with high hardness, high melting point, high conductivity, high thermal conductivity and good thermal shock resistance. Ultra high temperature materials used for manufacturing thermal protection parts shall have excellent properties such as high strength, high temperature resistance, oxidation resistance and thermal shock resistance. The main applications are refractory metals and their alloys, C-C composites, C-SiC composites and ceramic matrix composites. The mass fraction of zirconium disilicide is 10-15%. Adding this mass fraction of zirconium disilicide to the ceramic matrix composite can significantly reduce the sintering temperature of the material preparation.

2. Zirconium silicide can be used as lubricating material, wear-resistant material, semiconductor film, electronic material and ceramic material.

3. Deoxidizer. In the process of steelmaking, oxygen in molten steel is removed, and some ferroalloys can also remove other impurities in steel, such as sulfur and nitrogen.

4. Alloy additives. According to the composition requirements of steel grade, alloy elements are added into the steel to improve the properties of the steel.

Zirconium silicide, as a zirconium silicon intermetallic compound, is a kind of high-temperature ceramic material chemicalbook with high hardness, high melting point, high conductivity, high thermal conductivity and excellent thermal shock resistance. In view of these excellent physical and chemical properties, zirconium silicon intermetallic compound is a structural material or new engineering material that can be applied to high-temperature corrosive media.

5. Because silicon zirconium intermetallic compounds have excellent physical and chemical properties, zrsi2 is a structural material or a new engineering material that can be used as a high-temperature corrosion medium.

Study on the elasticity and anisotropy of zirconium silicide compounds formed by metal and silicon are metal silicides, which are divided into two categories:

1 refractory metal silicide refers to silicide of group IVB, VB and VIB elements of the periodic table, such as titanium silicide, zirconium silicide, tantalum silicide, tungsten silicide, etc.; 2 precious metal and near precious metal silicide, silicide target, platinum silicide, cobalt silicide, etc. in a short period, metal silicide is a relatively hard material with metallic luster, high conductivity, positive resistance humidity coefficient, and magnetism in most cases, Refractory metal silicides have high melting point, hardness and compressive strength, high creep strength at high temperature, medium density, tensile strength and good temperature mechanical properties. The reaction between metal and silicon reduces the activity of metal, so the chemical stability of silicides is quite good. Refractory metal silicides with high silicon content have good corrosion resistance and oxidation resistance at room temperature and high temperature, Disadvantages of metal silicide: very brittle at room temperature, low impact toughness and insufficient thermal shock resistance. The physical and chemical properties of metal silicides make them have many uses. First, silicides as high-temperature structural materials have good application prospects in aviation, aerospace and chemical industry. As functional materials such as high-temperature anti-oxidation coatings, magnetic materials and integrated circuit electrode films, they have been widely studied and applied. For example, fe2si ordered alloys have excellent soft magnetic properties and are widely used in audio, Magnetic head materials for video and card readers; Silicide is added into v2si, CoSi2 and mo2si. Due to its excellent conductivity, v2si is a superconducting A15 phase discovered by people, and its critical transition temperature is 17.1k; MoSi2 is widely used as electric heating element of high-temperature electric furnace and high-temperature anti-oxidation coating for aerospace due to its excellent conductivity and oxidation resistance. Similarly, metal silicide plays a very important role in the manufacturing of electronic devices. Because the resistance of silicide is lower than that of polycrystalline silicon, and the interface between silicide and silicon substrate is atomic level clean interface with good compatibility, it is widely used in the microelectronic manufacturing industry, It is widely used as Schottky barrier and interconnection material.