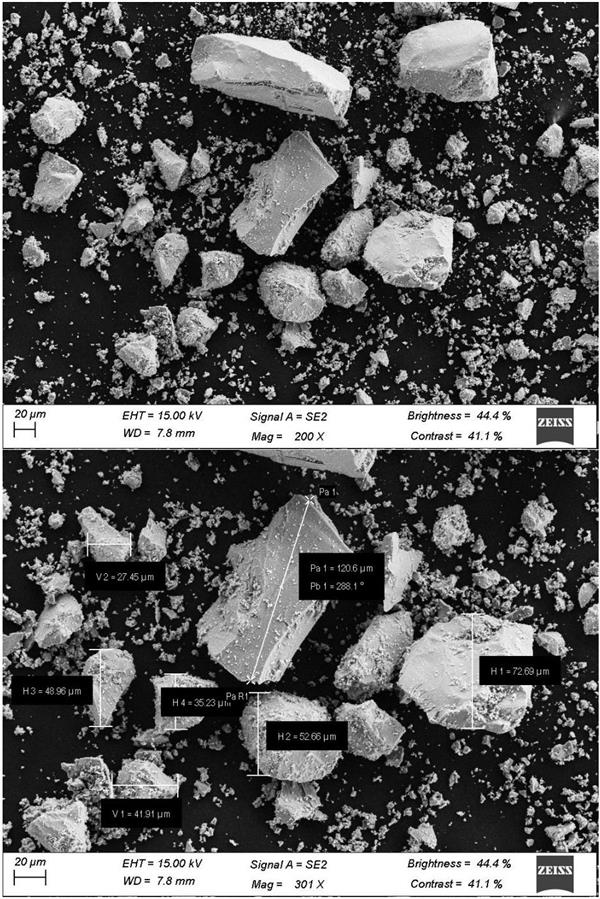

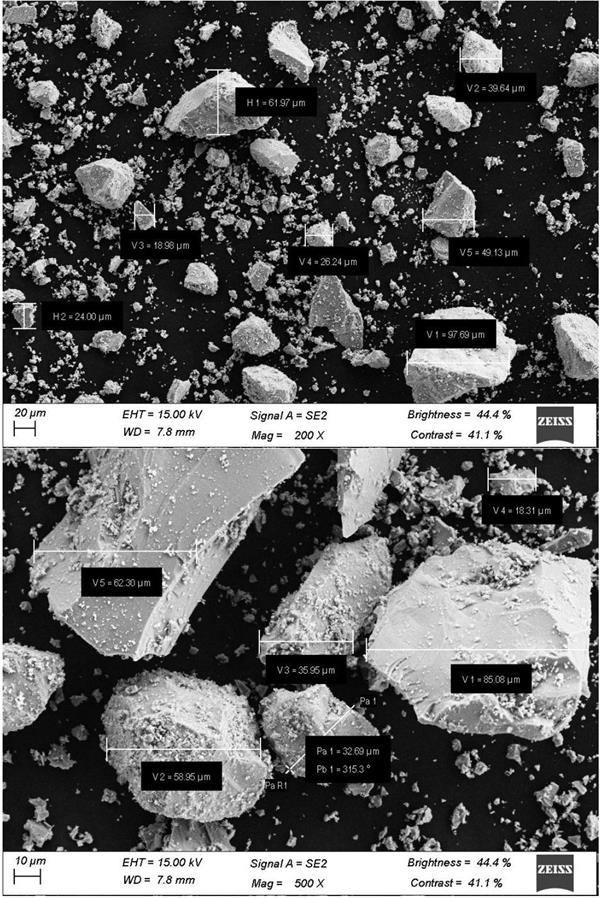

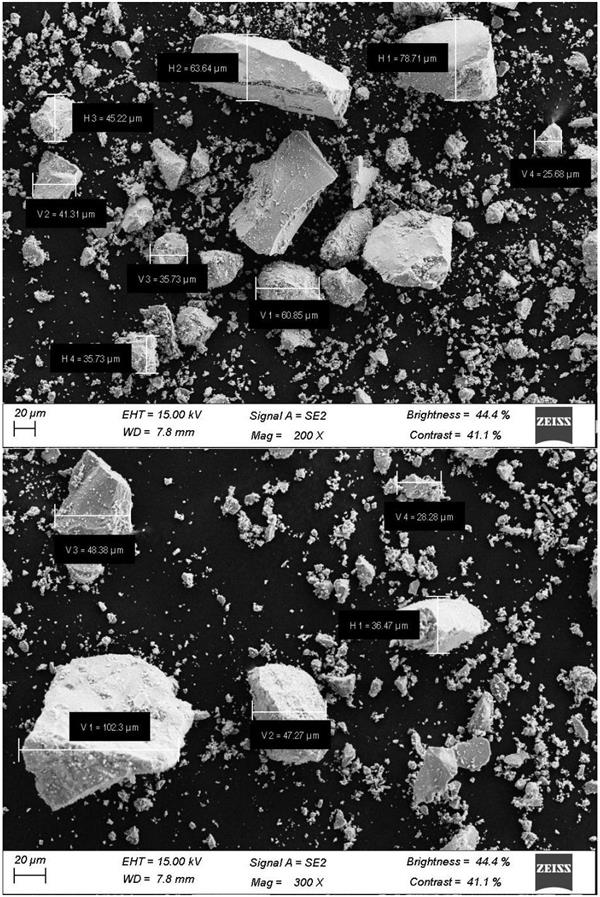

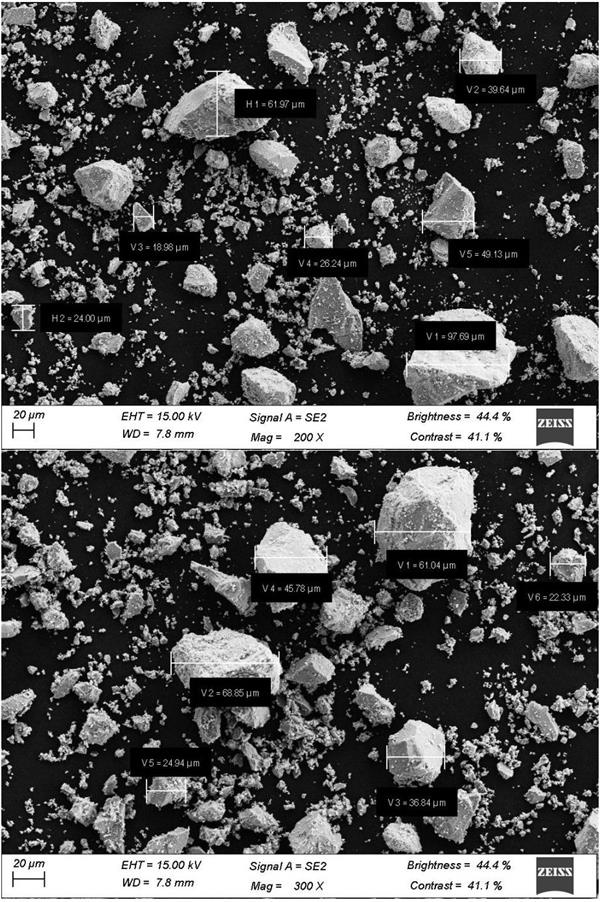

Ferro Silicide(FeSi2)

.jpg)

.jpg)

.jpg)

.jpg)

Chinese name: iron silicide

Chemical formula: FeSi ✪

Molecular weight: 119.975

CAS: 12022-99-0

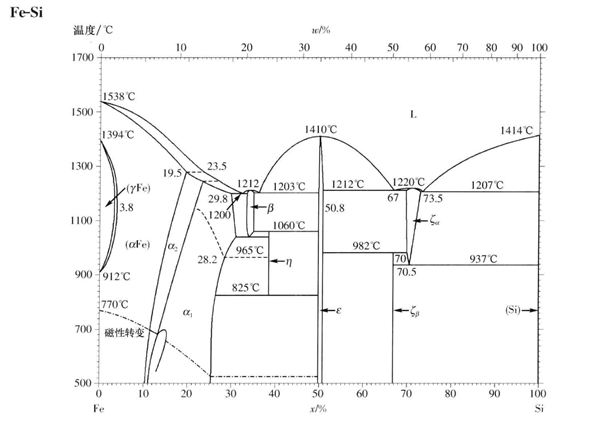

Melting point: 1410 ℃

Density: 4.79 g/cm ³

Performance: insoluble in water, nitric acid and hydrochloric acid, soluble in hydrofluoric acid and alkali liquor

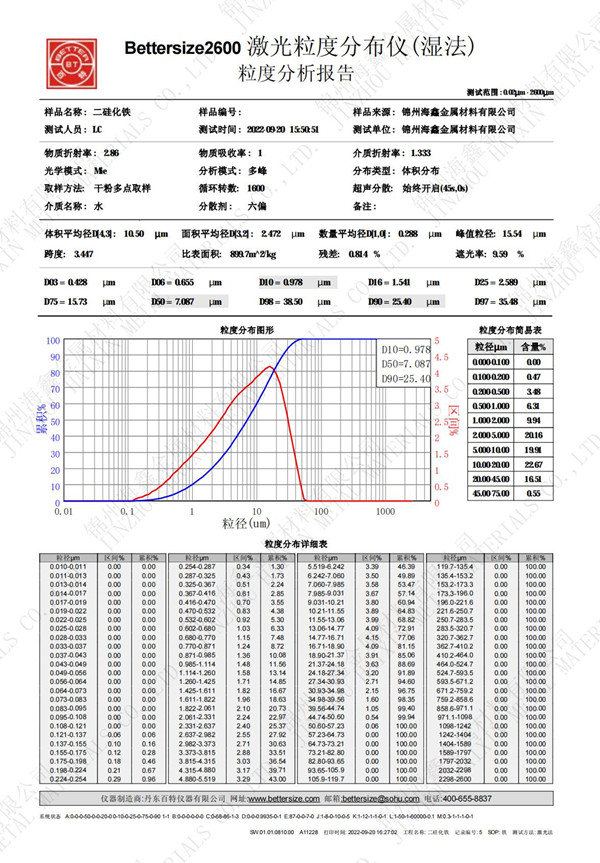

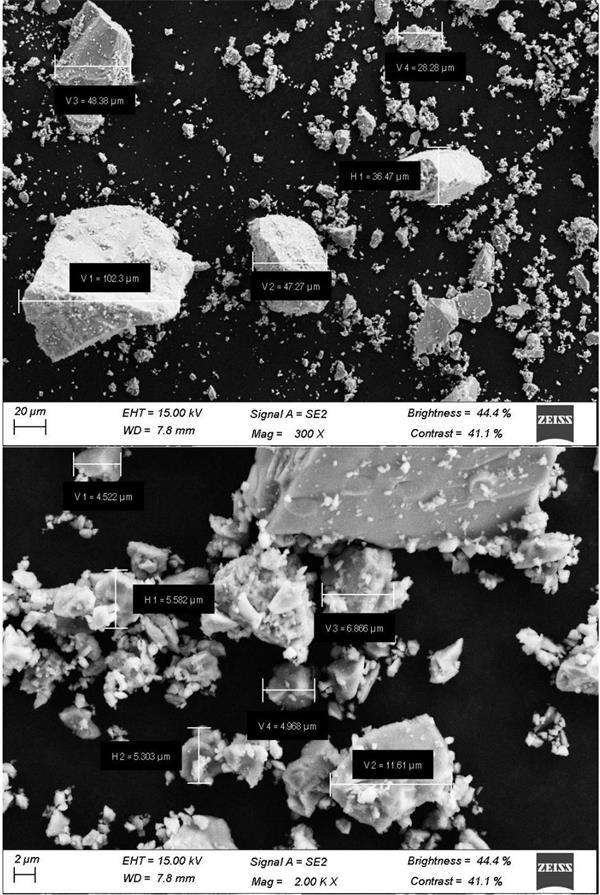

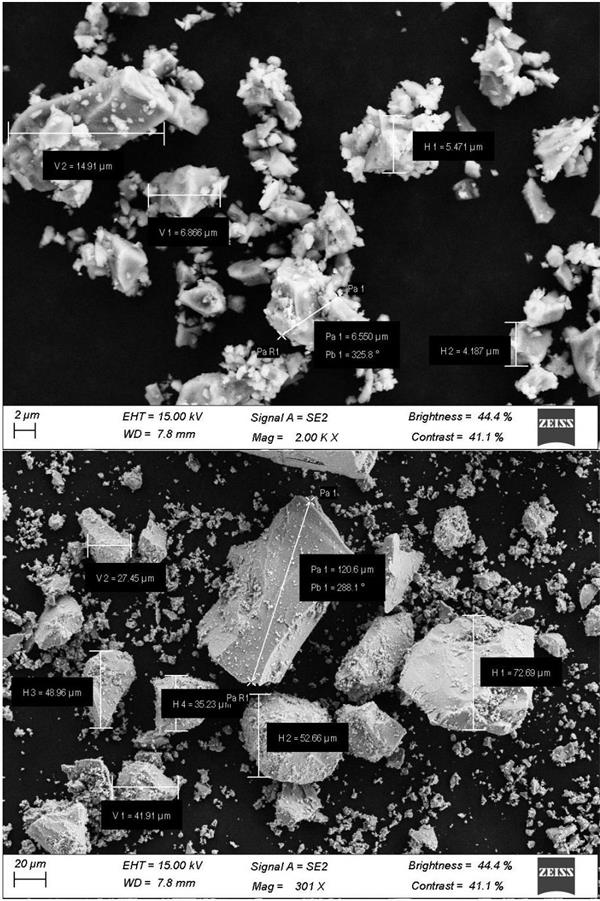

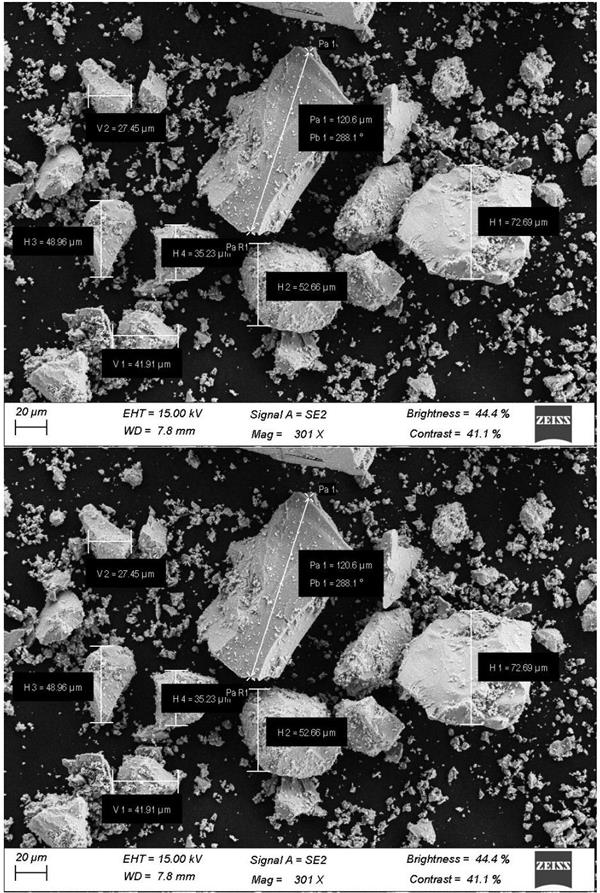

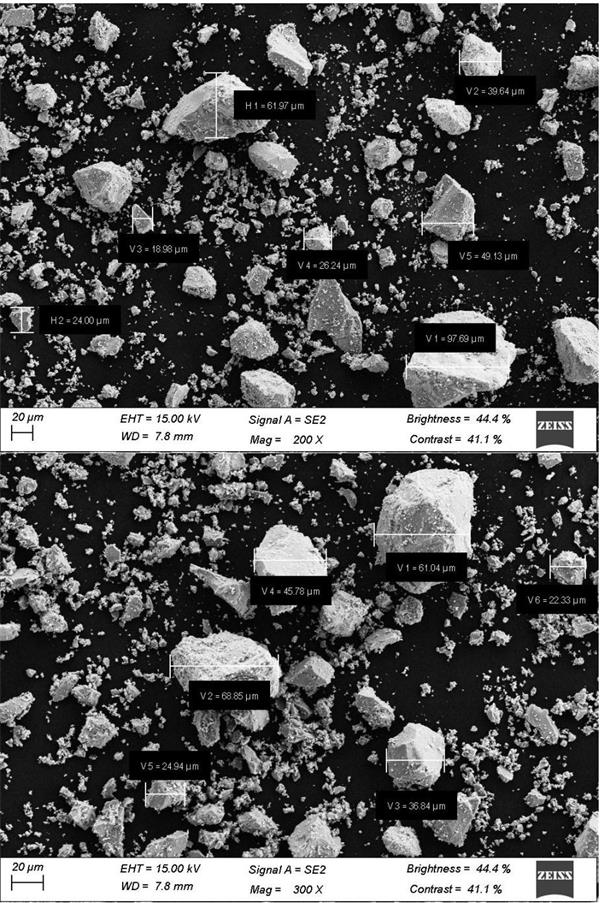

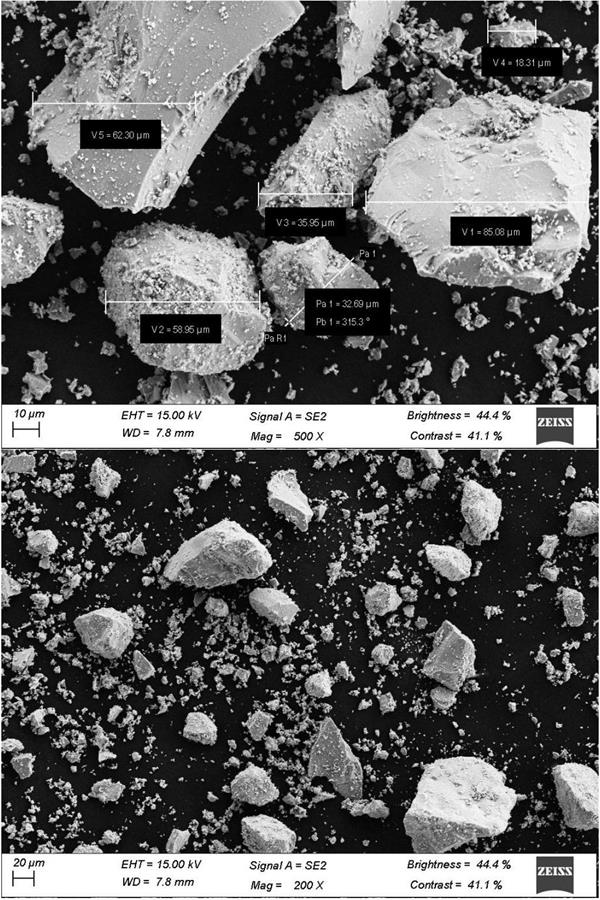

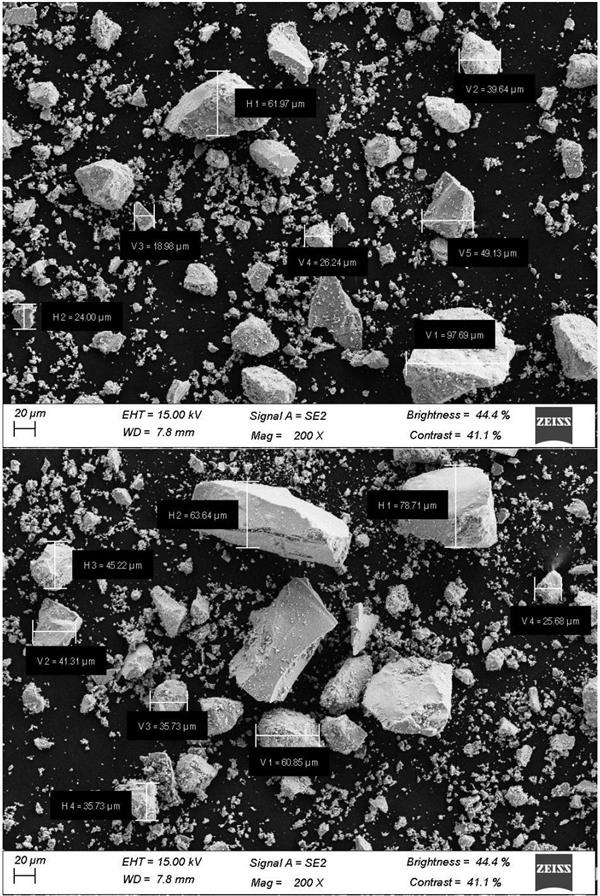

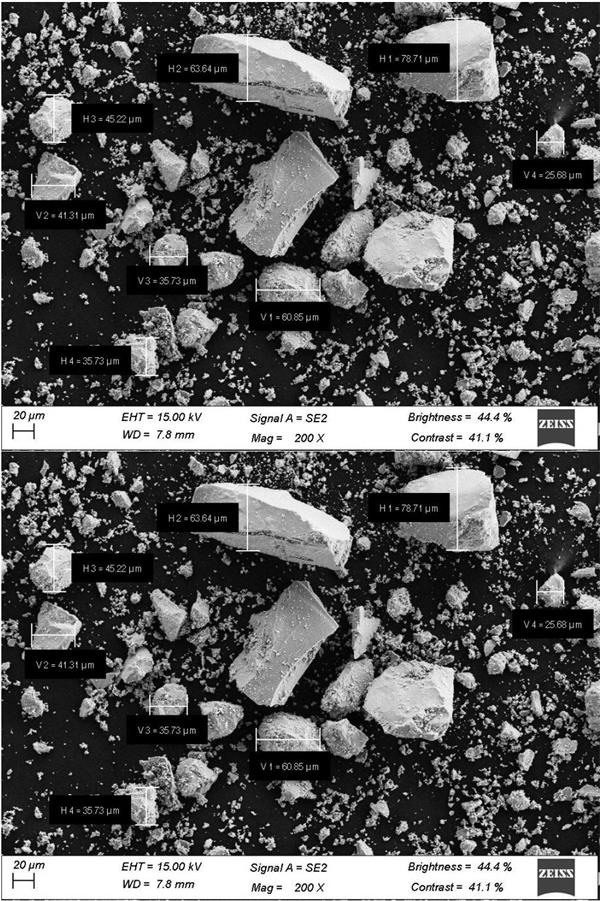

Appearance: grey powder

Production method of iron disilicide:

Mix iron powder and silicon powder in a molar ratio of 1:2, eutectic or sinter in vacuum or inert atmosphere.

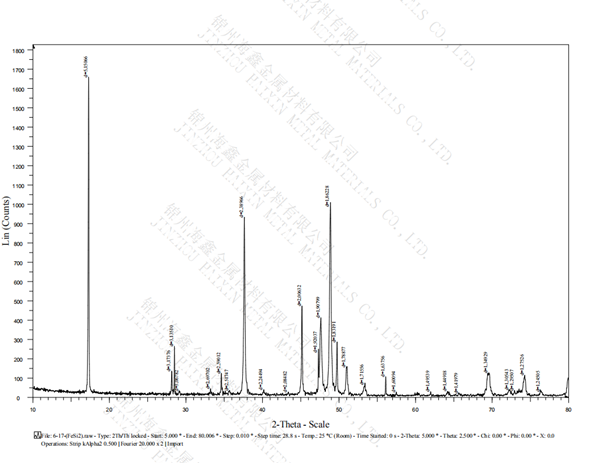

Iron silicide is an inorganic substance with the chemical formula of FeSi ∈, gray powder, odorless, tetragonal crystal, insoluble in water, which can be used as a catalyst for hydrogen catalytic oxidation and methanation, specifically as a deoxidizer of welding flux, humidity sensor, FeSi ∈ thermocouple, thermoelectric solar cell.

(1) It is used as deoxidizer and alloying agent in steelmaking industry. In order to obtain steel with qualified chemical composition and ensure the quality of steel, deoxidation must be carried out in the final stage of steelmaking. The chemical affinity between silicon and oxygen is great, so ferrosilicon is a strong deoxidizer for steelmaking, used for precipitation and diffusion deoxidization. Adding a certain amount of silicon in steel can significantly improve the strength, hardness and elasticity of steel. Therefore, ferrosilicon is also used as an alloying agent when smelting structural steel (silicon content 0.40-1.75%), tool steel (silicon content 30-1.8%), spring steel (silicon content 40-2.8%) and silicon steel for transformer (silicon content 2.81-4.8%). At the same time, it is an effective new technology to improve steel quality, reduce cost and save iron by improving inclusion morphology and reducing gas element content in molten steel. It is especially suitable for deoxidation of molten steel in continuous casting. Practice has proved that ferrosilicon not only meets the deoxidation requirements of steelmaking, but also has the desulfurization performance and has the advantages of large ratio and strong penetration. In addition, in the steelmaking industry, ferrosilicon powder is often used as the heating agent of the ingot cap to improve the quality and recovery of the ingot, because it can release a lot of heat when it is burnt at high temperature.

(2) It is used as inoculant and nodulizer in cast iron industry. Cast iron is an important metal material in modern industry. It is cheaper than steel, easy to melt and smelt, and has excellent casting performance and much better seismic resistance than steel. In particular, the mechanical properties of nodular cast iron reach or approach those of steel. Adding a certain amount of ferrosilicon into cast iron can prevent the formation of carbides in iron and promote the precipitation and spheroidization of graphite. Therefore, ferrosilicon is an important inoculant (to help precipitate graphite) and spheroidizer in the production of ductile iron.

(3) It is used as reducing agent in ferroalloy production. Not only is the chemical affinity between silicon and oxygen very high, but also the carbon content of high silicon ferrosilicon is very low. Therefore, high silicon ferrosilicon (or siliceous alloy) is a reducing agent commonly used in the production of low-carbon ferroalloy in the ferroalloy industry.

(4) Ferrosilicon is often used in the high-temperature smelting process of metallic magnesium in the Pidgeon process of magnesium smelting. The magnesium in CaO. MgO is replaced. Each ton of metallic magnesium produced will consume about 1.2 tons of ferrosilicon, which plays a great role in the production of metallic magnesium.

(5) Other purposes. The ground or atomized ferrosilicon powder can be used as the suspended phase in the mineral processing industry. It can be used as the coating of welding rod in the welding rod manufacturing industry. High silicon ferrosilicon can be used to manufacture silicone and other products in the chemical industry.