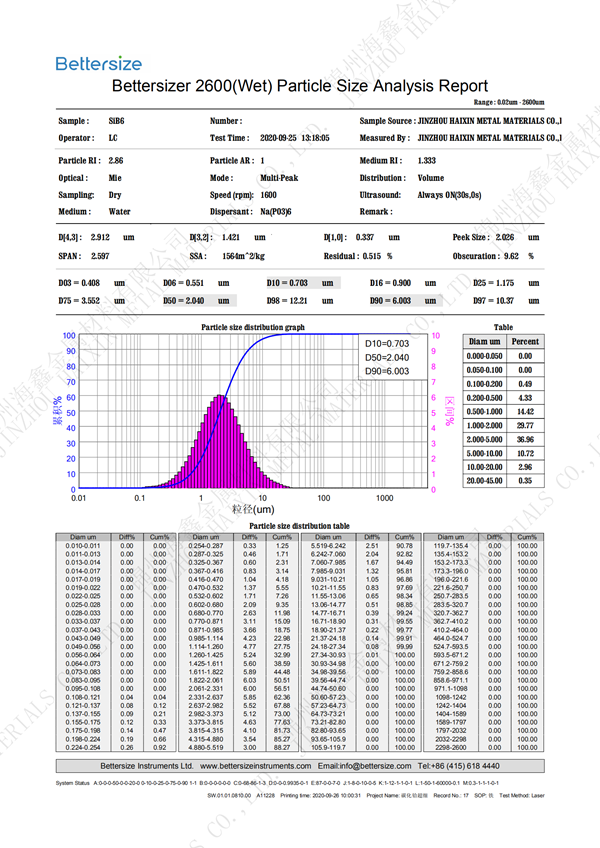

Silicon Boride Powder(SiB6)

.jpg)

.jpg)

.jpg)

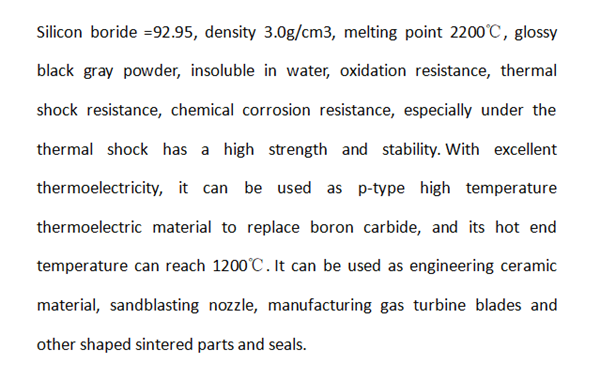

Product Name: silicon hexaborate

English Name: boron silicide (b6si); Boron silicide; Silicon boride; Hexaboron silicide

CAS:12008-29-6 [1]

EINECS:234-535-8

Molecular formula: b6si

Molecular weight: 92.952

Relative density: 3.0g/cm3

Melting point: 2200 ℃

Application of silicon hexaborate:

1.B6si can effectively promote the sintering of boron carbide ceramics and

improve the mechanical properties of materials.

2. Because silicon hexaborate has heat resistance and high impact resistance,

it is relatively cheap, so it is often used in resin grinding wheels and as the

main abrasive.

Explanation of silicon hexaborate terms: chemical formula sib6. Molecular weight

92.95. Black crystal. The relative density is 2.47. The hardness is between diamond

and ruby. It can conduct electricity. Insoluble in water. When heated in chlorine

and steam, the surface can be oxidized. It can be oxidized directly in boiling nitric

acid. Unchanged in molten potassium hydroxide. It decomposes in hot concentrated

sulfuric acid. Explanation of preparation terms: the mixture of silicon and boron can

be directly heated, the excess silicon can be removed with hydrofluoric acid and nitric

acid, and then the silicon triboride (b3si) in the mixture can be decomposed with

molten potassium hydroxide. The crystal structure of sib6 consists of interconnected

icosahedron (20 faceted polyhedron), icosahedron (26 faceted polyhedron) and isolated

silicon and boron atoms. Due to the size mismatch between silicon and boron atoms,

silicon can be used to replace boron in B12 icosahedron until the limit stoichiometric

ratio corresponding to sib2.89 is reached.

High purity silicon hexaborate process:

A low-cost and high-purity silicon hexaborate production process, boron trioxide and

potassium borohydride, in argon protection, after ball milling and mixing, are pressed

into blocks, loaded into a vacuum carbon tube furnace, evacuated, and maintained at

750 ℃ for 5 hours; Raise the temperature to 1250 ℃ and continue to maintain the

temperature until the pressure in the furnace is slightly positive, and the reduction

reaction is completely completed. Put the mixture of monomer boron and potassium

hydroxide in the graphite crucible into distilled water for heating, cleaning and drying

to obtain boron powder; The boron powder and silicon powder are milled and mixed,

and then loaded into the self creeping reaction kettle. The reaction kettle is evacuated,

and the vacuum degree is 1 Pa. The tungsten wire is heated by electricity, and the

zirconium powder is ignited. The high-temperature self creeping reaction is carried out.

The reaction is completed, the temperature is reduced, and the impurities are removed

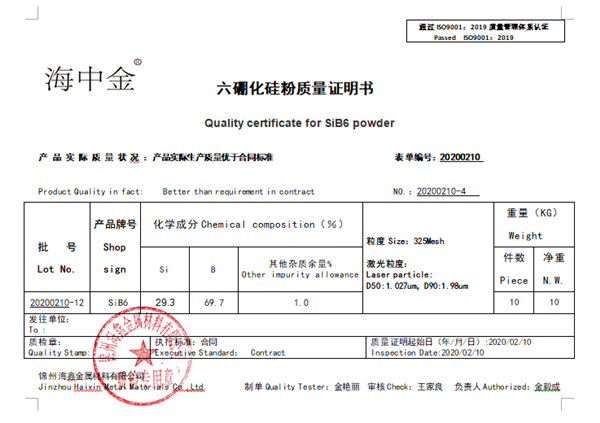

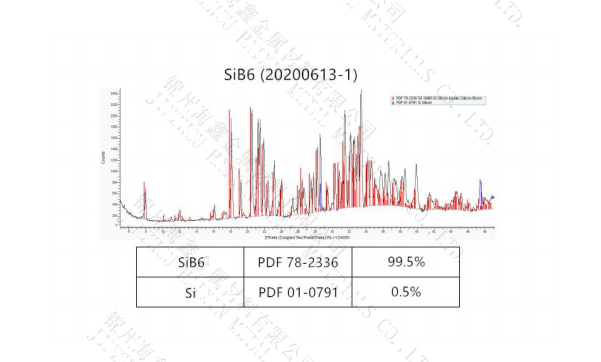

to obtain high-purity silicon hexaborate With boron trioxide and potassium borohydride

as raw materials, the raw material cost is relatively low, and the whole process is reasonable

and controllable. The purity of silicon hexaborate produced is 99.5%, which is suitable for

industrial production.