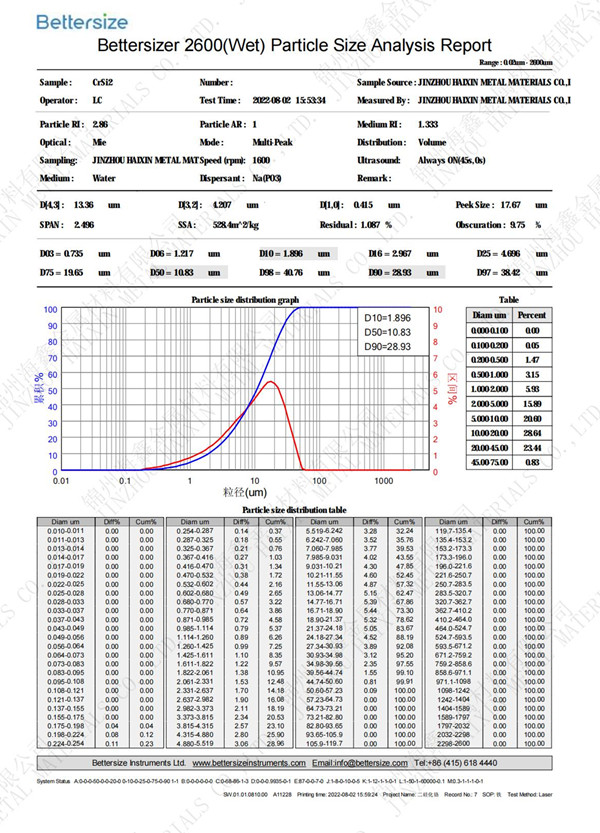

Chromium Silicide(CrSi2)

.jpg)

.jpg)

.jpg)

Chinese Name: chromium silicide

English Name: chromium silicide

CAS:12018-09-6

Density (g / ml, 25 / 4 ℃): 5.5

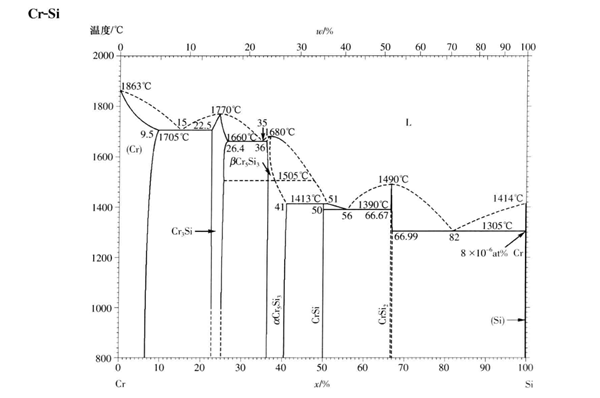

Melting point: 1490 º C

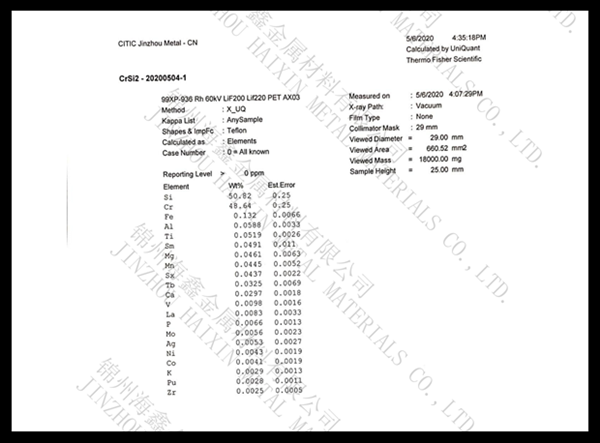

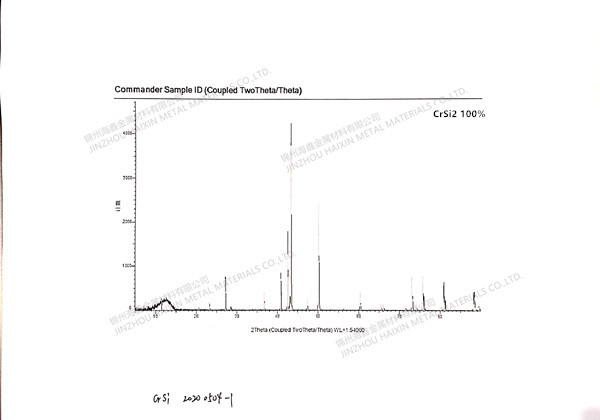

Molecular formula: CrSi2

Molecular weight: 108.16700

Accurate mass: 107.89400

Appearance: silver to black powder, odorless, insoluble in water, soluble in hydrochloric acid and hydrofluoric acid.

Stability: it will not decompose when used and stored according to specifications. Chromium silicide is a gray tetragonal prism crystal, insoluble in water, sulfuric acid and nitric acid, soluble in hydrochloric acid and hydrofluoric acid. Stable in air at normal temperature; At 100 ℃, the surface is oxidized; 4chemicalbook reacts violently with chlorine at 00 ℃ to form chromium trichloride and silicon tetrachloride.

Performance: chromium silicide film has high resistivity and low temperature coefficient of resistance. Gray cubic crystal, hexagonal crystal system, a = 04422nm, C = 06351nm, melting point close to 1550 ℃, chromium silicide film has high resistivity and low resistance temperature coefficient. Chromium silicide film has high resistivity and low temperature coefficient of resistance.

Preparation process:

1. After mixing the silicon powder and chromium powder, calcine it in hydrogen at 900 ~ 1100 ℃ and cool it. Alternatively, the mixture of chromium powder and silicon powder and the mixture of silicon dioxide powder and silicon powder are mixed evenly, roasted in a hydrogen gas stream, and the volatile SiO formed by SiO2 and Si powder escapes together with Na and K in the raw material to obtain CrSi2.

2. The melting point of Cr3Si (cubic crystal) is about 1710 ℃, Cr5Si3 (tetragonal crystal, melting point about 1600 ℃), CRSI (cubic crystal, melting point about 1600 ℃), CrSi2 and cr3si2 can be obtained by CO melting or sintering chromium and silicon powder in vacuum or under the protection of hydrogen.

3.48.1 parts (particle size: 1100) μ M U.M and 51.9 parts of chromium powder having a particle size of 50 μ M U.M and 3 parts of silica powder having a particle size of 10 μ M U.M was mixed with 1.5 parts of silicon powder. The two mixtures were homogenized again. Calcine in hydrogen gas stream at 1100 ℃ for 1h, and then calcine at 1430 ℃ for 10min. The volatile SiO formed by SiO2 and Si powder escapes together with Na and K in the raw material to obtain CrSi2 sintered body with fine powder containing only 0.5% Na × 10-6,K0.1 × 10-6。

Storage and transportation: store in a cool and ventilated warehouse. Keep away from kindling, heat source and packaging.