Titanium Boride Powder(TiB2)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Titanium diboride

CAS:12045-63-5

Properties:

melting point:2900-3225 ° C

density; 4.52 g / ml at 25 ℃ (lit.)

solid in hydrogen peroxide and sulfuric acid

chemical property:

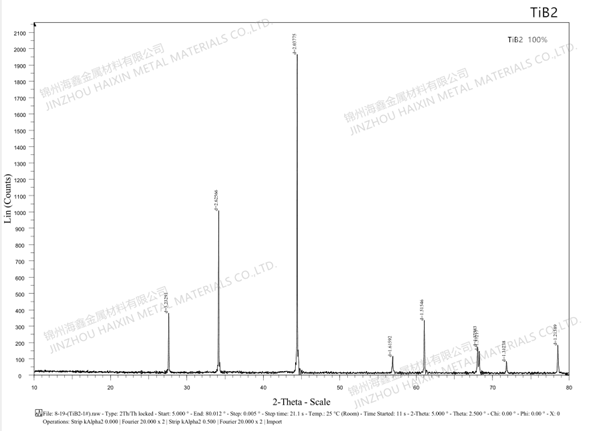

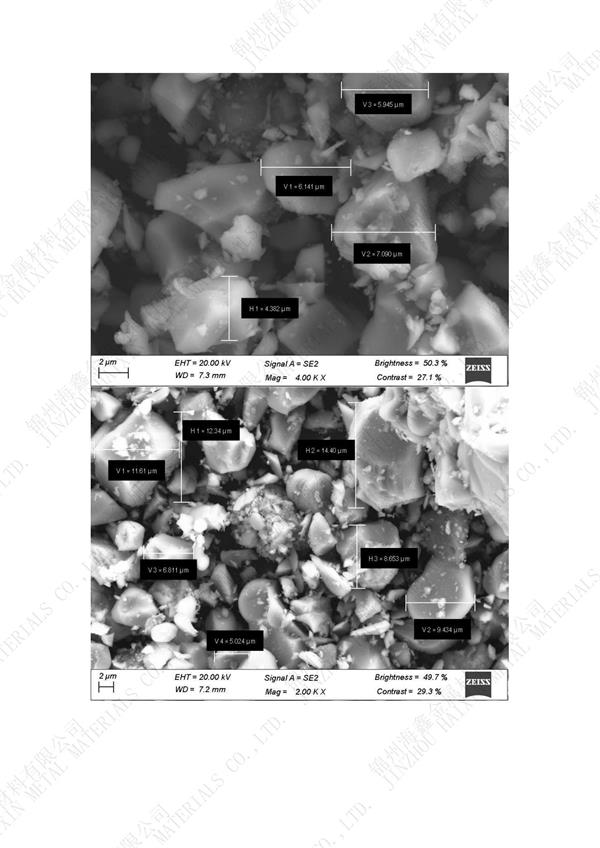

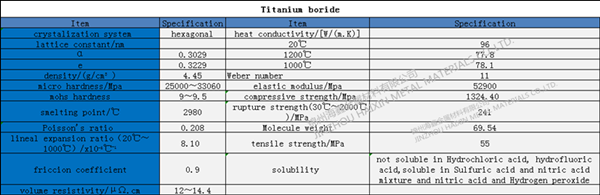

The product is grey hexagonal crystal with relative density of 4.50 and melting point

2900 ℃. It has high hardness and strength, good heat shock resistance, low electro

resistance and is not easy to be eroded by molten metal.

The powder is used in rocket nozzle, electrical contact and high temperature electrode

material, also can be used as abrasive.; conductive ceramics, tool ceramics, conductive

wear-resistant coating V use; conductive composite materials.

conductive boron nitride (steamboat),Produced with titanium diboride (TiB2) and boron

nitride (BN), is the main component of vacuum aluminizing equipment.

Ceramic cutting tools and parts. Titanium diboride ceramics are manufactured for wire

drawing dies, extrusion dies, sandblasting nozzles, sealing elements, cutting tools, etc.

Composite ceramic materials. Titanium diboride can be used as an important component

of multi-component composite materials. Titanium diboride can be used as a cutting tool

composite material with tic, tin, SiC and other materials. It can also be used as a component

to make armor protection material. It is the best material for various high-temperature parts

and functional devices. Cathode materials for aluminum electrolysis.

It can be used As the cathode material of aluminum reduction cell, TiB2 has good wettability

with molten aluminum, which reduces the power consumption of electrolytic aluminum and

prolongs the life of electrolytic cell.

It can also be made into PTC heating material and flexible PTC material, which is the

strengthening agent of A1, Fe, Cu and other metal materials. Application: used as rocket

nozzle, electrical contact, electrode materials; boron carbide method, also known as

carbothermal reduction method, it can be prepared by using TiCl4 and BCl3 as raw materials,

under H2 condition,deposition temperature is 800 ~ 1000 ℃, TiCl4 + 2bcl3 + 5h2 = TiB2 + 10hcl,

application to the milling and electricity level products.