How to break the high-temperature oxidation bottleneck of Nat. Commun. | MXene--- The introduction of O ∈ molecular competition mechanism

MXene shows great application potential in joule heating, energy conversion/storage, electromagnetic shielding and other aspects by virtue of its high conductivity and solution processability. However, MXene has poor stability in high-temperature and humid air environment, which greatly limits its application potential in actual high-temperature environment. Previous research shows that the oxidation process of MXene is mainly due to the destruction of the structure by oxygen and water molecules, and high temperature conditions will accelerate this irreversible process. Therefore, the anti-oxidation strategy of MXene materials under high temperature is the main problem in the future industrial production and application.

At present, the anti-oxidation strategy of Ti3C2Tx MXene is mainly to separate Ti3C2Tx MXene from O2 and H2O by changing the storage conditions of Ti3C2Tx (such as ultra-low freezing temperature, inert or reducing atmosphere, organic solvent), or using antioxidants (such as ascorbic acid and inorganic salts), as well as surface encapsulation of Ti3C2Tx. However, the above methods can only achieve certain anti-oxidation capacity under normal temperature aqueous solution conditions. How to improve the oxidation resistance of Ti3C2Tx MXene under high temperature in air or humid environment is an important problem to be solved.

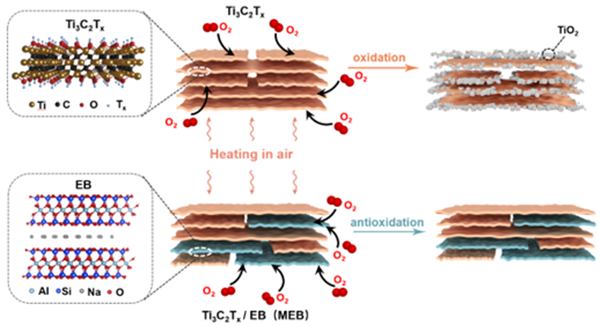

In order to solve this problem, the research team proposed an oxygen competition mechanism, using a high-temperature resistant nano layered material - bentonite (EB), which has stronger O2 adsorption capacity than Ti3C2Tx MXene. More importantly, after O2 saturated adsorption on EB, due to the coupling between Ti3C2Tx MXene and EB, the adsorption of O2 molecules on the surface of Ti3C2Tx MXene can be effectively inhibited, thus realizing the oxidation resistance at high temperatures. Based on this mechanism, Ti3C2Tx/EB (MEB) composite can have excellent stability at 400 ℃ and higher in air and humid environment.

Recently, the team of Xiao Xu from University of Electronic Science and Technology of China, together with the team of Zhou Liujiang and the team of Wen Qiye, designed layered Ti3C2Tx/EB (MEB) composites using the oxygen competition mechanism. Theoretical calculation shows that the stable EB at high temperature has a stronger coupling effect with oxygen molecules, so it can preferentially adsorb O2 molecules in composite materials compared with Ti3C2Tx, thus reducing the corrosion of oxygen molecules on Ti3C2Tx. More importantly, when the EB in the nanometer thick Ti3C2Tx/EB heterojunction saturates and adsorbs oxygen, it will weaken the hybridization between the O-p orbital and the Ti-d orbital in the new O2 molecule, further inhibiting the adsorption of Ti3C2Tx on the O2 molecule. The experiment proved that the introduction of EB greatly improved the thermal stability of Ti3C2Tx in air, and increased the complete oxidation temperature of Ti3C2Tx from 600 ℃ to 920 ℃. More importantly, the oxidation resistance of MEB will not be affected by the distribution of Ti3C2Tx surface functional groups.

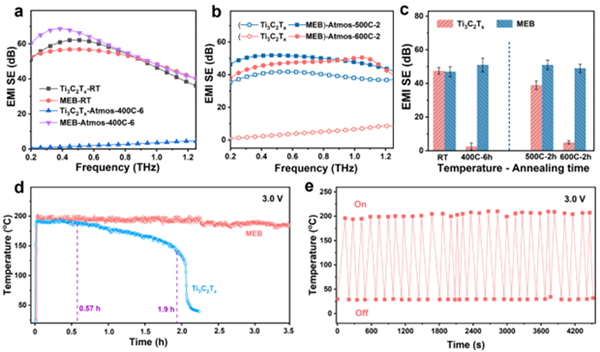

MEB can be used for terahertz electromagnetic shielding in high-temperature oxidation environment. Experiments show that MEB still shows 50 dB and 48 dB electromagnetic shielding effectiveness after being calcined at 400 ℃ for 6h and 600 ℃ for 2h respectively in the atmosphere, while Ti3C2Tx has completely oxidized and lost terahertz electromagnetic shielding performance under the same conditions. In addition, MEB reached the maximum temperature of 198 ℃ at the heating rate of 20 ° C s − 1 under the driving voltage of 3V, and remained stable for more than 3.5h. Under the voltage on/off condition, MEB's steady-state temperature was basically the same, reflecting MEB's rapid thermal response, stable high-temperature electrothermal performance and thermal cycle stability.

This achievement was published online on the top international journal Nature Communications, entitled: High property stability in air of Ti3C2Tx MXene based composite with extracted bentonite

Picture and text guided reading

Fig. 1 High temperature oxidation behavior of Ti3C2Tx and MEB in oxygen.

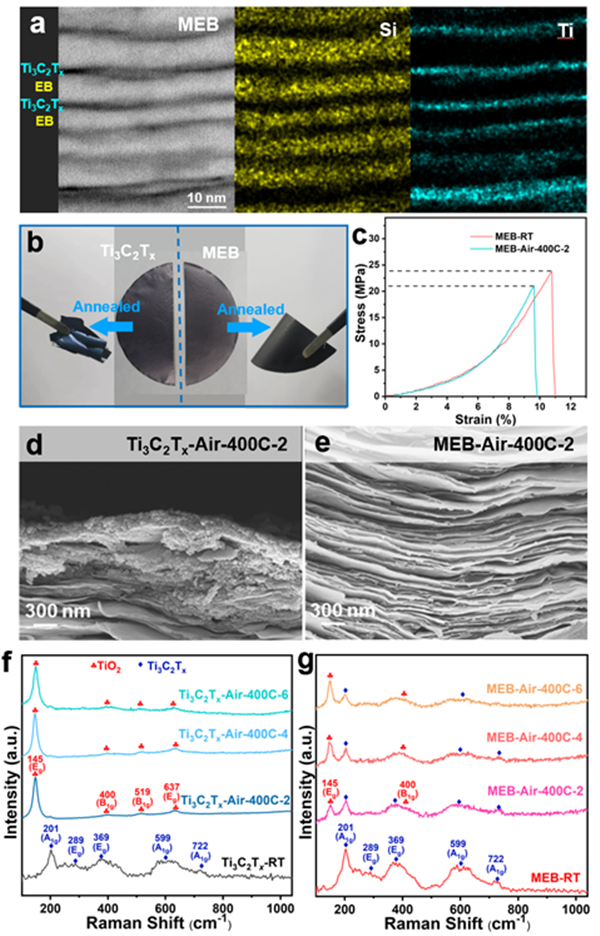

Figure 2. High temperature oxidation performance of Ti3C2Tx and MEB in oxygen. (a) MEB section STEM (EDX) image. (b) Optical photos of Ti3C2Tx and MEB films calcined at 400 ℃ in air for 2 hours. (c) Stress strain curves of MEB-RT and MEB-Air-400C-2. (d) (e) SEM diagram of Ti3C2Tx and MEB films calcined at 400 ℃ in air for 2 hours. (f) Raman spectra of Ti3C2Tx films before and after treatment in air at 400 ℃ for 2,4,6 hours. (g) Raman spectra of MEB films before and after treatment in air at 400 ℃ for 2,4,6 hours.

Figure 3. MEB high temperature resistance mechanism study. (a) Thermogravimetric mass spectrometric analysis of Ti3C2Tx, (b) EB and (c) MEB in air. (d) A charge density difference diagram of stable configurations of O2 molecules adsorbed on Ti3C2O2, EB and Ti3C2O2/EB heterostructures. The yellow area is charge accumulation, and the green area is charge loss. (e) O1s X-ray photoelectron spectroscopy (XPS) of Ti3C2Tx-RT and MEB-RT.

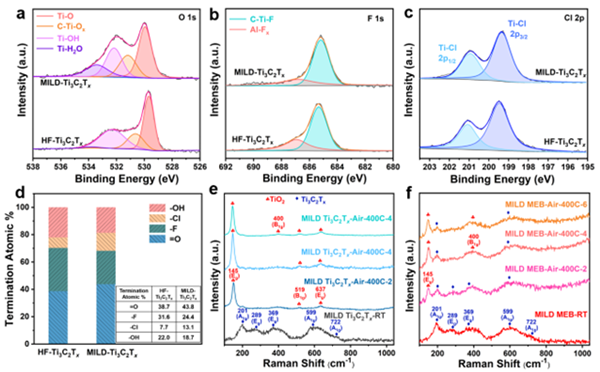

Figure 4. High temperature resistance of MILD-Ti3C2Tx and HF-Ti3C2Tx with different functional group distribution and MILD MEB in oxygen. (a-c) XPS of O1s, F1s and Cl 2p of MILD-Ti3C2Tx and HF-Ti3C2Tx films. (d) Functional group distribution of MILD-Ti3C2Tx and HF-Ti3C2TX measured by XPS. (e) MILD-Ti3C2Tx Raman spectra before and after treatment in air at 400 ℃ for 2,4,6 hours. (f) Raman spectra of MILD MEB before and after air treatment at 400 ℃ for 2,4,6 hours.

headquarters

To sum up, a Ti3C2Tx MXene/EB composite was prepared in this paper. Based on the strong adsorption capacity of EB and the strong coupling effect between EB and oxygen molecules, EB in the composite MEB can preferentially adsorb oxygen molecules. At the same time, after EB saturates oxygen adsorption, the Ti3C2Tx/EB interface coupling effect will further inhibit the adsorption of oxygen molecules on the Ti3C2Tx surface, so that the composite can inhibit the oxidation of Ti3C2Tx in high temperature (higher than 400 ℃) air environment. The mechanism and effect of inhibiting Ti3C2Tx oxidation are independent of the distribution of Ti3C2Tx surface functional groups. As a terahertz shielding material, MEB is a promising terahertz shielding material with high temperature resistance, and its terahertz EMI SE reaches 48 dB after calcination at 600 ℃. At the same time, MEB with high temperature oxidation resistance showed excellent performance in Joule heating and thermal cycle experiments, expanding the potential application of MEB. The oxidation resistance strategy proposed in this paper provides ideas and methods for designing other high-temperature oxidation resistant two-dimensional composites.