A method for preparing cobalt silicide

Summary:

The current cobalt silicide preparation process usually adopts the double metal method, namely the Co/Ti method. By depositing a certain thickness of Ti metal above the Co metal, the influence of external conditions (such as oxygen in the purification chamber and reaction chamber) and natural oxides on the silicon wafer surface on the formation of cobalt silicide is eliminated. We deposit a layer of metal in PVD on the top and bottom of Co, where Ti or TiN on the upper surface can eliminate the influence of external conditions through reaction or blocking, while Ti under Co can eliminate the influence of natural oxides on the silicon surface. At the same time, in order to eliminate the disadvantage of epitaxial growth caused by thick Ti below, there is a strict requirement for the thickness of a layer of Ti metal on the silicon wafer surface when depositing, that is, the reaction between Co and silicon cannot be affected, and epitaxial growth cannot be caused, so it is generally required to be below 2nm.

Background technology:

With the continuous development of integrated circuits, silicide technology has been introduced into the manufacturing process. And it has developed from the initial polycide (silicide on polysilicon) process to today's silicide (self-aligned silicide) process. Cobalt silicide (CoSi2) is widely used in 0.18 micron and micron processes. It has the following advantages: low resistivity, good thermal stability, and the temperature of silicide formation will not increase with the reduction of line width. At present, there are three methods to prepare silicides: one is to directly deposit Co (Co) on silicon surface by PVD (physical vapor deposition), as shown in Figure 1; The other is to use double-layer metal, the main body is also Co, and PVD deposits a thin layer of Ti (titanium) metal below the Co metal, as shown in Figure 2; The third one is also a double-layer metal. PVD is used to deposit a thin layer of Ti (titanium) metal on the top of Co metal, as shown in Figure 3. The preparation method in Figure 3 has been widely used. Either way, silicide is formed through thermal process (generally RTP (rapid heat treatment process)) after metal deposition. Co metal is very sensitive to the external conditions when forming silicides, especially the natural oxides on the silicon surface and the oxygen in the atmosphere have a great impact on the formation and quality of silicides (where silicon oxide exists, cobalt silicides cannot be formed). Therefore, only in the initial research stage did people deposit Co on the surface of silicon wafer to directly generate silicide. Later, in order to remove the influence of oxides on the silicon wafer surface (even after cleaning, the oxygen on the silicon wafer surface cannot be completely removed), people first deposited a layer of Ti (titanium) on the silicon wafer surface and then deposited Co, so that the chemical activity of Ti can be used to reduce silicon oxide, which is conducive to the later formation of cobalt silicide. But in this case, the growth of cobalt silicide is epitaxial, which has the problems of slow growth rate and high stress in silicide. Later, a process of putting Ti (or Ti N (titanium nitride)) metal on Co was developed, which prevented the influence of oxygen in the atmosphere in the purification chamber and reaction chamber on the formation of silicides from Co. However, the quality of silicide prepared with TiN is not very good, so in fact, Ti metal is used. Good quality silicides can be prepared by using Ti metal, and the square resistance of silicides with different linewidths is nearly equal. Theoretically, Ti on cobalt will complete the reduction of natural silicon oxide on the silicon wafer surface through diffusion. However, the reaction between Ti metal and silicon wafer surface oxide is not direct enough, and the reaction mechanism is complex, so the reduction characteristics of Ti metal may not be best used.

Invention content:

The purpose of the invention is to propose a new method for preparing cobalt silicide, which not only combines the advantages of the two methods for growing silicide, but also eliminates their respective disadvantages. The method for preparing cobalt silicide proposed by the invention is realized by using a sandwich structure, that is, PVD deposition of Ti, Co, Ti or TiN on the surface of silicon substrate in order to form low resistance CoSi2 (cobalt disilicide). In this way, the advantages of the above two methods can be combined. The sandwich structure is characterized from the silicon substrate upwards as shown in Fig. 4. The obvious disadvantage of the method shown in Figure 2 is that silicide is grown by epitaxy, which has the problems of slow growth speed and large residual stress. The key to overcome these shortcomings is to eliminate the epitaxial growth problem caused by Co diffusion through the Ti layer. The invention requires to reduce the thickness of the lowest layer of Ti as much as possible, for example, less than 4nm, so that it can not only give play to the characteristics that it is easy to react with the oxides on the silicon surface, but also will not affect the reaction between Co and silicon due to its too thick thickness. After adding a layer of Ti or TiN to the upper surface of Co, the chemical activity of Ti or the characteristics of TiN as a barrier layer can be well used to prevent the influence of oxygen in the atmosphere. It can be seen that the use of sandwich structure has significant advantages. The specific steps for preparing cobalt silicide proposed by the invention are as follows:

1. Three layers of Ti/Co/Ti (N) (N means the uppermost layer can be Ti or TiN) are deposited on the cleaned silicon wafer surface in turn by PVD method. The thickness of Ti in the lowest layer is 1-4nm, the thickness of Co in the middle is 10-20nm, and the thickness of Ti (N) in the uppermost layer is 4-8nm;

2. Adopt the method of rapid thermal annealing at a lower temperature; 500 ℃ - 600 ℃, forming Co Si (cobalt silicide);

3. Corroded the unwanted and unreacted Co metal and Ti (N) metal;

4. CoSi2 (cobalt disilicide) with low resistance is formed by rapid thermal annealing at higher temperature: 800 ℃ - 900 ℃. The invention adopts a novel sandwich structure and combines the advantages of two methods of growing silicide, so that the preparation of silicide is not affected by the residual oxide on the silicon surface and the oxygen or water vapor in the atmosphere, the resistance stability of the silicide is significantly improved, the resistance size is easy to control, and there is no stress concentration problem, so the requirements of silicide process on equipment and conditions are greatly reduced.

Description of attached drawings

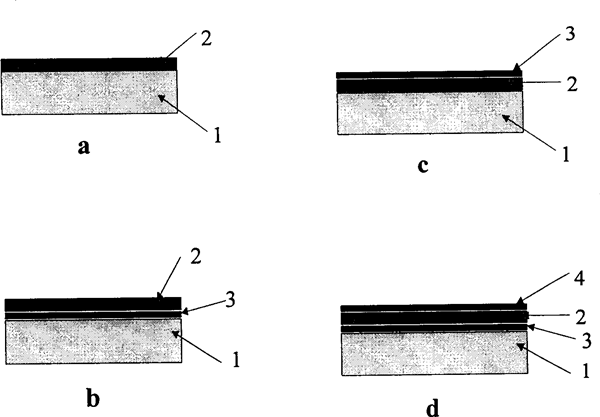

Figure 1a is an illustration of a deposit layer for preparing a silicide using a single layer of Co metal.

Fig. 1b is an illustration of the deposit layer for preparing silicide using Ti/Co bimetals. Figure 1c is an illustration of the deposit layer for preparing silicide using Co/Ti bimetal.

Fig. 1d is a diagram of the deposit layer of the silicide prepared with Ti/Co/Ti (N) three layers of metal. Label in the figure: 1 is silicon substrate, 2 is Co layer, 3 is Ti layer, and 4 is Ti or TiN layer. Specific embodiments

The present invention is further described by embodiments.

1. Clean the silicon wafer surface with diluted hydrofluoric acid, and successively deposit Ti/Co/Ti on the silicon wafer surface by PVD method

(N) Three layers of metal with a thickness of 2nm/15nm/6nm.

2. CoSi was formed by rapid thermal annealing at 550 ℃.

3. Corroded the unwanted and unreacted Co metal and Ti (N) metal.

4. It is rapidly annealed at 850 ℃ to form CoSi2 with low resistance. The cobalt silicide prepared by the above process has good performance.