In order to solve the problem that it is difficult to construct a three-dimensional continuous conductive and thermal conductive network in polyolefin, an origami process was proposed and a seamless graphene network structure with oriented arrangement of

Source: ACSNano.

The principle. https://doi.org/10.1021/acsnano.2c01716

01 introduction

With the rapid development of semiconductor devices towards high integration, high power density and high transmission speed, "electromagnetic pollution" and "hot spots" are considered to be the key to have a negative impact on the stability and reliability of the system, which puts forward higher requirements on the electromagnetic interference shielding performance and thermal conductivity of the peripheral components of the equipment. Polyolefins such as polyethylene (PE) and polypropylene (PP) have the advantages of versatility, lightweight and chemical inertness, and are widely used in the electronic industry. However, their electromagnetic shielding efficiency (EMI SE) < 1 dB and have low thermal conductivity (0.2 – 0.5 w M-1 k-1). For the same reason as

To improve these two properties, people prepare polyolefin composites by adding nano fillers. Unlike traditional polymers which have low viscosity state (such as epoxy resin) before curing or can be dissolved in a solvent (such as polyvinyl acetate) under normal conditions, polyolefins are difficult to dissolve in a common solvent under normal temperature and still show a high viscosity state when melting. Therefore, melt blending has become a popular method to prepare polyolefin composites, while solution blending or infiltration process is not feasible, which brings technical challenges to improve the physical properties of polyolefin composites.

02 introduction to achievements

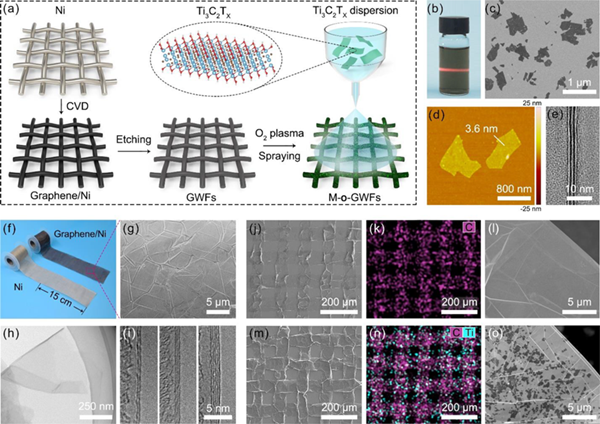

Recently, Lin Zhengde, researcher of Ningbo Institute of materials, Chinese Academy of Sciences, Dr. Dai Wen, and WAN Yanjun, associate researcher of Shenzhen Institute of advanced technology, Chinese Academy of Sciences (co corresponding author), etc. hydroxylated graphene woven nets (gwfs) prepared by chemical vapor deposition (CVD), and then sprayed ti3c2tx mxene nanosheets. The interfaces between the two were connected by hydrogen bonds to obtain m-o-gwfs, After being transferred to PE film, m-o-gwf / PE film was folded by origami process and hot pressed to obtain composite material.

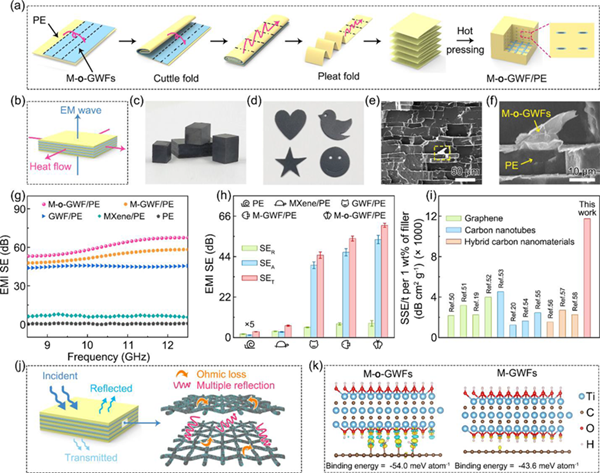

Based on the highly oriented arrangement structure of seamless graphene and the hydrogen bond interaction between mxene and graphene interface, m-o-gwfs / PE composite exhibits good electromagnetic interference shielding performance (≈ 61.0 dB) and excellent thermal conductivity (9.26 w M-1 k-1), and the SSE / T per unit mass (≈ 11742 DB cm2 g-1) is much better than other carbon nanomaterials / polyolefin composites. Meanwhile, The percentage increase in thermal conductivity per unit mass (≈ 719%) set a record in nanofiller / polyolefin composites. In addition, the method is universal and can be used to improve the properties of other thermoplastic polymers.

The above achievements were published on ACS Nano with the title of "enhanced electromagnetic shielding and thermal conductive properties of polyfin composites with a ti3c2tx mxene graphene framework connected by a hydrogen bonded interface". Ningbo Institute of material technology and engineering of Chinese Academy of Sciences was the first unit of the paper.

03 text guide

Fig. 1 Preparation and characterization of m-o-gwfs

(a) The preparation process of mxene nanosheets modified gwfs by hydrogen bonding; (b) Photos of mxene dispersion; (c) SEM, (d) AFM and (E) HR-TEM images of mxene nanosheets; (f) Photos before and after the growth of graphene with nickel mesh; (g) SEM, (H) tem and (I) HR-TEM images of graphene; (J) SEM, (k) C element distribution and (L) enlarged SEM images of gwfs; (m) SEM of m-o-gwfs, (n) elemental distribution of C and Ti, and (o) enlarged SEM images.

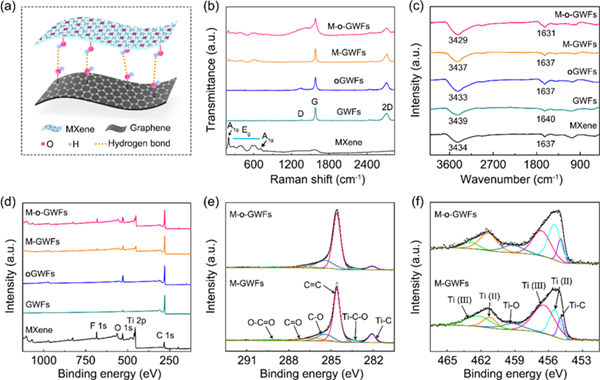

Fig. 2 spectral analysis of m-o-gwfs

(a) Schematic diagram of hydrogen bond formation between mxene and hydroxyl fossil graphene interface; (b) Raman, (c) FTIR, (d) XPS spectra and (E) fine spectra of C 1s and (f) Ti 2p of each sample.

Fig. 3 preparation, structure and electromagnetic shielding performance of m-o-gwf / PE Composite

(a) Preparation process of m-o-gwf / PE; (b) Schematic diagram of preferred direction of electromagnetic shielding and thermal conductivity test; (C, d) photos and (E, f) cross-sectional topography of m-o-gwf / PE composite; (g) EMI Se and (H) corresponding ser, sea and set of each sample; (i) Comparison of SSE / T per unit mass fraction of polyolefin composites; (j) Electromagnetic shielding mechanism of m-o-gwf / PE composite; (k) Differential charge density of m-o-gwfs and m-gwfs.

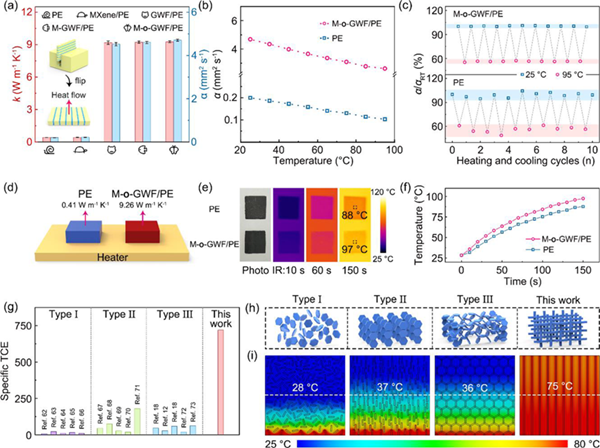

Fig. 4 thermal conductivity of m-o-gwf / PE Composite

(a) Thermal diffusion coefficient and thermal conductivity of the sample; (b) relationship between thermal diffusion coefficient and temperature and (c) cyclic thermal stability of m-o-gwf / PE and PE; (d) Schematic diagram of infrared thermal image testing device; Changes of surface temperature of m-o-gwf / PE and PE with heating time: (E) infrared thermogram; (f) Temperature rise curve. (g) Comparison of specific TCE of m-o-gwf / PE preferred direction with other polyolefin nanocomposites; (h) Different types of filler structures in polyolefin nanocomposites; (i) Comparison of heat transfer simulation results of four packing structures.

Fig. 5 universality and actual electromagnetic shielding and thermal conductivity of m-o-gwf / PE Composite

(a) thermal conductivity and (b) EMI se of m-o-gwf / thermoplastic polymer composites; (c) Comparison of SSE / T per 1 wt% of filler and specific TCE of thermoplastic polymer composites; (d) schematic diagram and (E) photo of electromagnetic shielding performance of m-o-gwf / PE composite; (f) physical photo and (g) explosion diagram of LED module; (H) schematic diagram and (I) physical diagram of cooling LED lamp with m-o-gwf / PE as heat sink; (j) The change of LED lamp surface temperature under different input power and the relationship between (k) corresponding steady-state temperature and power density; (l) M-o-gwf / PE has good thermal cycling stability.

04 Summary

In order to solve the problem that it is difficult to build a three-dimensional continuous conductive and heat conductive network in polyolefin, a paper folding process was proposed and a seamless graphene network structure with orientation and arrangement of ti3c2tx mxene pre modified by hydrogen bonding was successfully constructed in PE matrix. The prepared m-o-gwf / PE composite exhibited excellent thermal conductivity (9.26 w M-1 k-1) and good electromagnetic interference shielding performance (≈ 60.2 dB) at low filling content (≈ 3.0 wt%). The seamless graphene framework prepared by CVD method overcomes the disadvantage of high interfacial resistance between adjacent nanosheets of the packing network assembled by traditional graphene nanosheets. Moreover, mxene and graphene are connected by hydrogen bonds instead of simple weak van der Waals interaction. At the same time, we prove that the optimal design of the interface between Nano fillers is an effective strategy to improve the physical properties of composites under the same filler content. It is worth noting that this method is universal and can be used to improve the performance of other thermoplastic polymers. It has a good application prospect in effectively suppressing electromagnetic interference and effectively cooling electronic devices.

Literature link

Enhanced Electromagnetic Shielding and Thermal Conductive Properties of Polyolefin Composites with a Ti3C2Tx MXene/Graphene Framework Connected by a Hydrogen-Bonded Interface, ACS Nano, 2022. https://doi.org/10.1021/acsnano.2c01716