3D printing of sodium friendly mxene aerogel to realize high surface capacity sodium battery

Source: Mu Mai 2021

[background]

Metallic sodium has become an ideal anode material for sodium ion batteries because of its high theoretical capacity, low cost and abundant resources. However, the real feasibility of sodium metal anode is still hindered by the uncontrolled sodium dendrite problem.

[introduction to achievements]

In view of this, Professor Wang Ye of Zhengzhou University and others manufactured an artificial three-dimensional (3D) layered hydrophilic v2ctx/rgo CNT micro grid aerogel through direct ink writing and 3D printing technology, and further used it as the substrate of Na metal to prepare Na@V2CTx /RGO CNT sodium metal negative electrode. V2ctx/rgo CNT electrode can achieve an excellent cycle life of more than 3000 hours (2 Ma cm-2, 10 MAH cm-2), with an average coulomb efficiency of 99.54%. More attractive, it can even operate stably at 5 Ma cm-2 for more than 900 hours, with an ultra-high area capacity of 50 MAH cm-2. The in-situ and non in-situ characterization and density functional theory simulation analysis show that v2ctx with rich sodium affinity functional groups can effectively guide the nucleation and uniform deposition of sodium metal, so as to achieve dendrite free morphology. In addition, the Na@V2CTx /RGO CNT negative electrode and na3v2 (PO4) 3@C -The full battery paired with RGO cathode can provide a high reversible capacity of 86.27 MAH g-1 after 400 cycles at 100 Ma g-1. This work not only illustrates the excellent sodium deposition chemistry on the sodium loving v2ctx/rgo CNT micro grid aerogel electrode, but also provides a method to manufacture advanced sodium metal negative electrode by 3D printing. Relevant paper achievements were published on ACS Nano on June 6, 2022 under the title of "3D printed societal v2ctx/rgo-cnt mxene microgrid aerogel for stable Na metal anode with high area capacity".

[introduction to the full text]

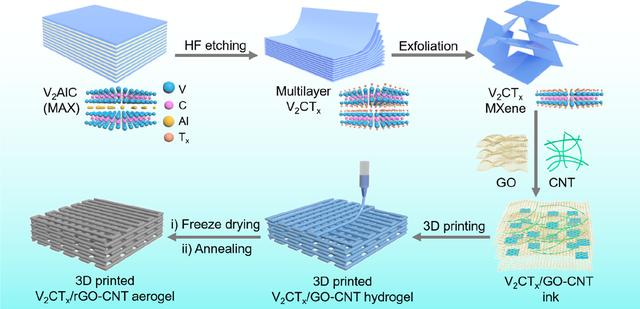

Figure 1 shows the preparation process of v2ctx/rgo CNT micro grid aerogel electrode printed in 3D.

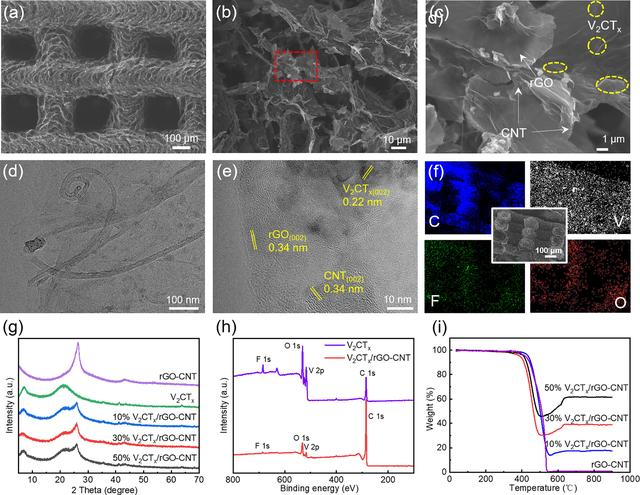

Figure 2 shows the SEM image of (A-C) 30% v2ctx/rgo CNT micro grid aerogel. (d) TEM and (E) HRTEM images of v2ctx/rgo CNT nanocomposites. (f) SEM and EDS element mapping of v2ctx/rgo CNT micro grid aerogel cross section. (g) XRD patterns of RGO CNT, v2ctx and v2ctx/rgo CNT nanocomposites. (h) XPS spectra of v2ctx mxene and v2ctx/rgo CNT. (i) TGA curves of RGO CNT and v2ctx/rgo CNT nanocomposites.

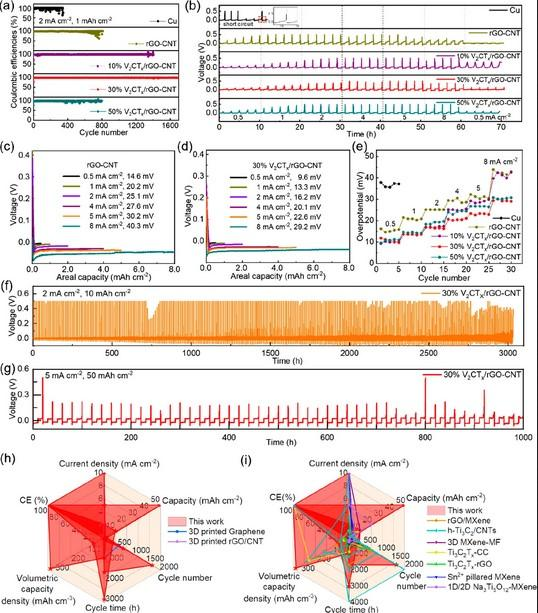

Figure 3 shows the electrochemical performance of Na metal plating / stripping on two-dimensional planar copper foil, RGO CNT and different v2ctx/rgo CNT electrodes. (a) Ce of electrode at 2 Ma cm-2 and 1 MAH cm-2. (b) Rate performance of various electrodes at a current density of 0.5 to 8 Ma cm-2 with a plating / stripping duration of 1 hour. (b) The illustration in shows the short circuit of the copper foil electrode. (c) Voltage capacity curves of RGO CNT and (d) 30% v2ctx/rgo CNT micro grid electrodes at different current densities. (e) The nucleation overpotential of each electrode at different current densities. Cycling performance of 30% v2ctx/rgo CNT electrodes at (f) 2 Ma cm-2 and 10 MAH cm-2 and (g) 5 Ma cm-2 and 50 MAH cm-2. (h) Comparison radar chart of electrochemical performance of sodium metal anode with 3D printed graphene based substrate and (I) different mxene based sodium metal anode.

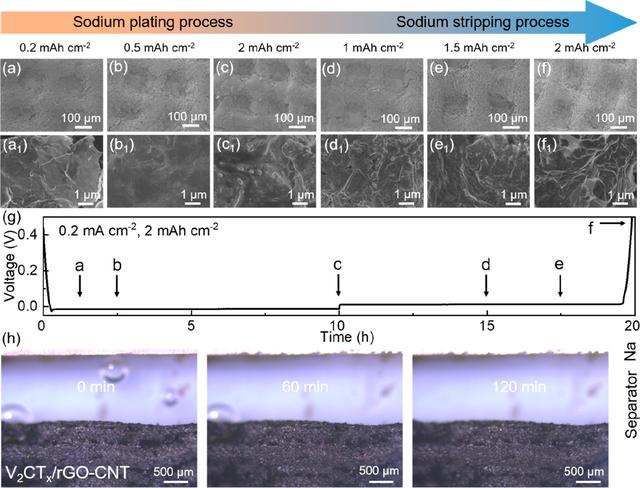

Figure 4 shows: (A-F) morphological evolution of deposition and stripping of Na on 3D printed v2ctx/rgo CNT electrode. (g) Corresponding deposition stripping curve. (h) In situ optical microscope image of Na deposited at 1 Ma cm-2 current density for 2 hours on v2ctx/rgo CNT electrode.

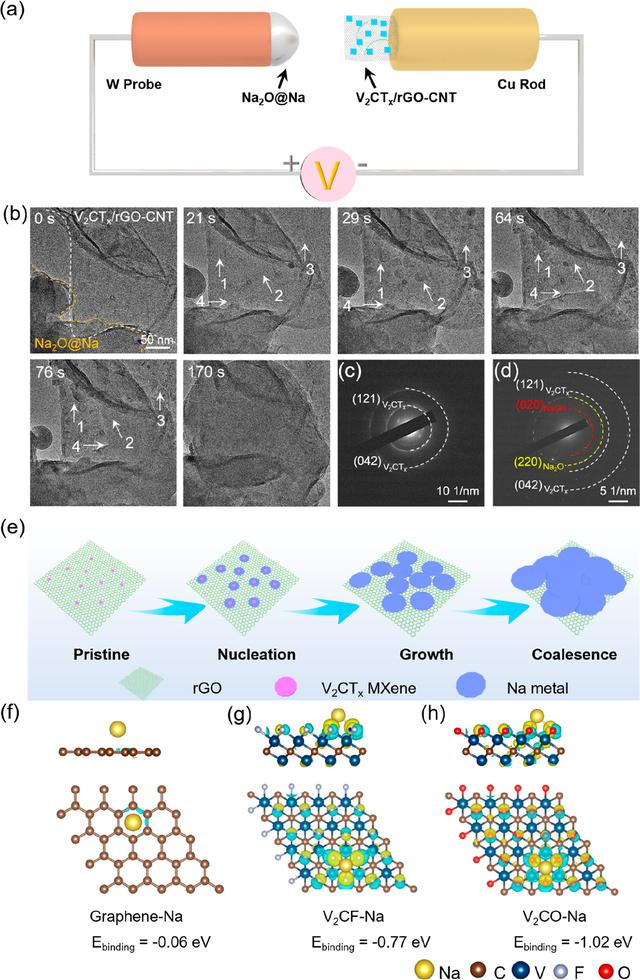

Figure 5 shows: (a) schematic diagram of in situ TEM device. (b) In situ TEM snapshot of v2ctx/rgo CNT sodium plating process. (c) Saed pattern after original v2ctx/rgo CNT and (d) sodium deposition. (e) Schematic diagram of sodium deposition process. Binding energies between Na and (f) C (graphene), (g) f (v2cf) and (H) O (v2co) calculated based on DFT.

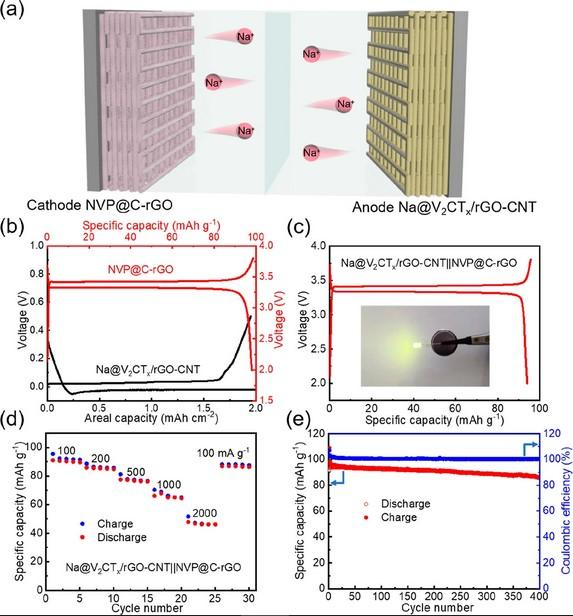

Figure 6 shows: Na@V2CTx /rGO-CNT|| NVP@C -Electrochemical performance evaluation of RGO full cell. (a) Schematic of the full battery. (b) NVP@C -RGO positive and Na@V2CTx /Constant current charge discharge (GCD) curve of RGO CNT negative electrode. (c) GCD curve of 100 Ma g-1 current density filled battery. (d) The rate performance of the full battery within the current density range of 100-2000 Ma g-1. (e) Cycle performance of the full battery at 100 Ma g-1 current density and corresponding CE.

[paper link]

Zixuan Wang, Zhenxin Huang, Hui Wang, Weidong Li, Bingyan Wang, Junmin Xu, Tingting Xu, Jinhao Zang, Dezhi Kong, Xinjian Li, Hui Ying Yang, and Ye Wang, 3D-Printed Sodiophilic V2CTx/rGO-CNT MXene Microgrid Aerogel for Stable Na Metal Anode with High Areal Capacity, ACS NANO, 2022.

https://doi.org/10.1021/acsnano.2c01186